johnswie

Junior Member

- Joined

- Aug 19, 2023

- Posts

- 17

- Reaction score

- 2

- Location

- simi valley

- First Name

- john

- Truck Year

- 1978

- Truck Model

- c10

- Engine Size

- 350

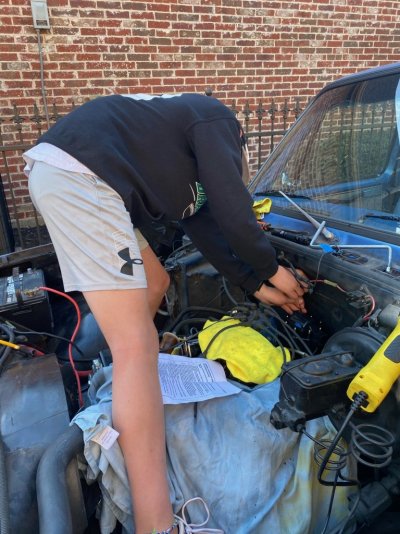

First time attempting something as in depth as this. Most of it looks pretty straightforward. What I’m most confused and concerned about, is messing with the timing. Do I absolutely need to rotate the engine to TDC before removing the distributor? I’ve seen some guys just mark the rotor and vacuum diaphragm and then remove it. They don’t however show what happens after. Do they have to retime it? I’ve also never used a timing light. And if you do have to rotate the engine. How do you do it? Like I said, never done anything like this so clear, detailed explanations are appreciated. Also, if in case I do mess up the timing. Will starting it damage the engine? Thank you