WP77

Junior Member

- Joined

- Jun 2, 2024

- Posts

- 20

- Reaction score

- 9

- Location

- Naples, Idaho

- First Name

- Steven

- Truck Year

- 1987

- Truck Model

- V10

- Engine Size

- 350

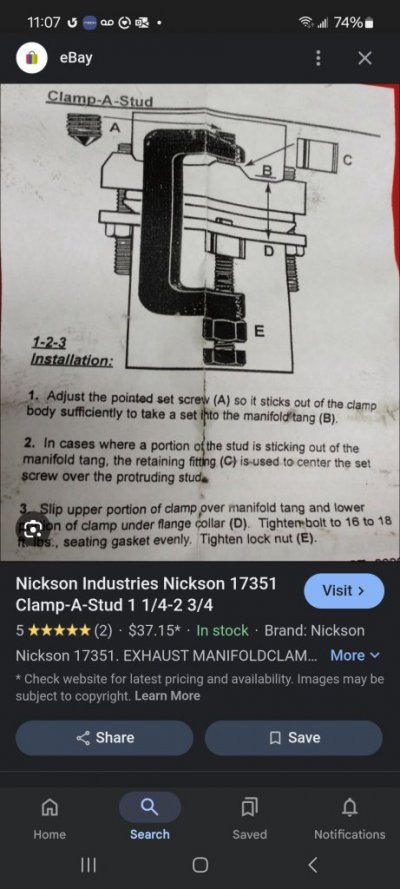

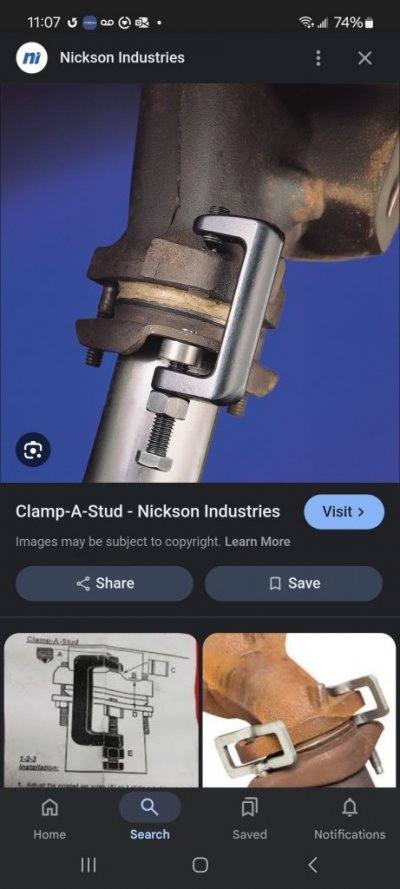

I'm getting ready to install a new 700R4 and 208 transfer case in my 87 V10. When I took the crossover exhaust pipe off, one bolt on each manifold broke off flush with the manifold. I've tried heating, drilling and easy outs to no avail. I'm not interested in trying to remove both exhaust manifolds, because I'm sure that will lead to even more broken bolts. I need to get this thing back running for my daughter since it's already been down 2 weeks. I'm guessing if I just use 2 bolts on each flange side I'll have leaks. Is there any type of hack, just to get by for a bit? I see those build your own flange kits. Does anyone know if those will work in conjunction with the factory flange? Maybe a way to add the 3rd bolt.