1987 GMC Jimmy

Automobile Hoarder

- Joined

- Jan 23, 2016

- Posts

- 5,848

- Reaction score

- 2,390

- Location

- Mississippi

- First Name

- Jesse

- Truck Year

- 1987

- Truck Model

- V1500 Jimmy

- Engine Size

- 350

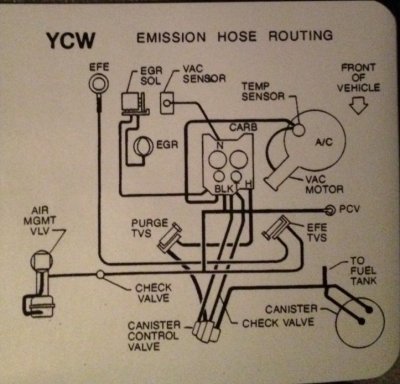

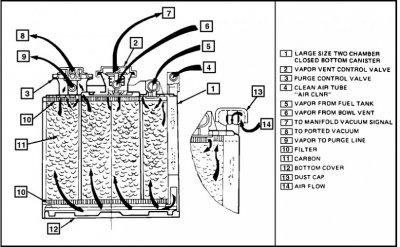

The title is basically it. I was pulling vacuum lines off my carburetor, and the fattest one that goes to the purge valve for the charcoal canister leaked gasoline out. Now, I flooded the carburetor a couple times while I was having ignition control module problems so I don't know if some could have leaked in there with vacuum happening, but I was also wondering if gas was getting sucked out of the canister and getting past the purge valve. When I put my face by the canister either in the engine bay or in the wheel well, I can smell gas, and it's raw but not overpowering. I have an intermittent backfire out of the tailpipe and a lot of misfiring. It'll idle correctly one minute and start missing really bad until it slowly dies or it'll just abruptly die even when it's running okay. I'm getting ECM codes 13, 44, and 45. They'll come and go with no apparent pattern (not hard codes), but it favors the lean exhaust. Oxygen sensor is new, and I haven't had any problems with it in the past. I don't think it's that because the car would at least run in limp home mode, and it's not even doing that. It actually broke down about 100 feet from my driveway the other day. I was driving with my come and go SES light, the car backfired brownish-blackish smoke, and died about a mile and a half from my house and wouldn't start for a few minutes. The car will always start but dies or starts misfiring shortly thereafter. Anyways, I managed to coast it pretty far, but I live on a hill so I didn't quite make it all the way. I've checked for a burnt exhaust valve and nada. I checked the valve train for any problems in actuation, lash, or pushrod bending and it all looks great. It's still got a tick, though, right at the passenger side bank. Carb is getting good fuel, but I'll check the filter just to be safe. And it's getting good spark. When it runs right, it'll show about 19 in. of Hg on the vacuum gauge, but that'll fall down once it starts to run crappy. It'll just sound like its running on seven cylinders, then six, and so on to where it sounds like a 2 stroke small engine, and I'll shut it off because it won't die sometimes, just keep going EGR valve is also fairly new and no codes for that. 305 has 80,000 miles on it. The only thing I've thought to replace are the intake gaskets. It's too tight to spray a combustible in there, but if anyone has any suggestions, I'll take them and run with them.

Last edited: