MannyDantyla

Full Access Member

- Joined

- Jan 13, 2015

- Posts

- 319

- Reaction score

- 15

- Location

- Lawrence, KS

- First Name

- Danny

- Truck Year

- 1983

- Truck Model

- K10

- Engine Size

- sbc350/sm365/np205

Alright, let me give ya a rundown of all that I've done the the front wheel bearings..

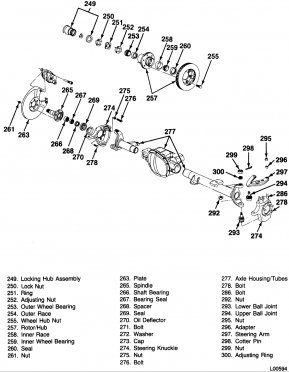

About a month ago, the driver-side front wheel bearing went bad - it was making a chirping noise and the wheel could wobble when it was off the ground - so I replaced it. Actually, there's three bearings: the inner and outer wheel bearing and the axle spindle needle bearing. I got lazy and din't replace the axle spindle needle bearing, only the other two which weren't in too bad a condition TBH. When I opened it up, the hub nuts were loose (I didn't hardly even need the special tool to remove them) so I assumed that was the issue.

Only a week or two after that it started to make a little bit of sound again. But it wasn't until a few days ago that it got real noisy and loud. So last night I opened it up again. The wheel could wiggle side to side with it off the ground, but the nuts were't loose. I think I didn't seat the bearing properly (the procedure for seating the bearings is just crazy). But this time I took the axle spindle off too and I could see the the axle spindle needle bearing was bad! Stupid lazy me for not replacing it the first time. I replaced it this time but I didn't replace the other two bearings, they seamed alright. However, the grease surrounding the bad axle spindle needle bearing had little bits of metal grit in it from the bad bearing. I looked but I don't think this traveled into the other bearings but I didn't look that hard really.. I put the wheel back on and this time I checked to make sure the wheel couldn't wiggle before I lowered the truck back to the ground.

But there's still a noise coming from the driver-side front wheel! It's slightly different than what it was soundling like before yesterday's repair, but not the chirping noise from before the original repair. It's more like a chattery kind of noise that gets a little louder as I come to a stop but can't be heard once the truck is stopped. It's not nearly as in sync with the wheel speed as the original chirping noise. I still think it's the wheel bearing and not the throughout bearing because it doesn't matter if clutch is in or not. I don' think it's the differential because it doesn't matter if I'm speeding up or slowing down. I have no idea if it's the tramsission or TC but it doesn't sound like it's coming from there.

Do you think I just need to replace the bearings again?

Help?

About a month ago, the driver-side front wheel bearing went bad - it was making a chirping noise and the wheel could wobble when it was off the ground - so I replaced it. Actually, there's three bearings: the inner and outer wheel bearing and the axle spindle needle bearing. I got lazy and din't replace the axle spindle needle bearing, only the other two which weren't in too bad a condition TBH. When I opened it up, the hub nuts were loose (I didn't hardly even need the special tool to remove them) so I assumed that was the issue.

Only a week or two after that it started to make a little bit of sound again. But it wasn't until a few days ago that it got real noisy and loud. So last night I opened it up again. The wheel could wiggle side to side with it off the ground, but the nuts were't loose. I think I didn't seat the bearing properly (the procedure for seating the bearings is just crazy). But this time I took the axle spindle off too and I could see the the axle spindle needle bearing was bad! Stupid lazy me for not replacing it the first time. I replaced it this time but I didn't replace the other two bearings, they seamed alright. However, the grease surrounding the bad axle spindle needle bearing had little bits of metal grit in it from the bad bearing. I looked but I don't think this traveled into the other bearings but I didn't look that hard really.. I put the wheel back on and this time I checked to make sure the wheel couldn't wiggle before I lowered the truck back to the ground.

But there's still a noise coming from the driver-side front wheel! It's slightly different than what it was soundling like before yesterday's repair, but not the chirping noise from before the original repair. It's more like a chattery kind of noise that gets a little louder as I come to a stop but can't be heard once the truck is stopped. It's not nearly as in sync with the wheel speed as the original chirping noise. I still think it's the wheel bearing and not the throughout bearing because it doesn't matter if clutch is in or not. I don' think it's the differential because it doesn't matter if I'm speeding up or slowing down. I have no idea if it's the tramsission or TC but it doesn't sound like it's coming from there.

Do you think I just need to replace the bearings again?

Help?