nitrocharger

Junior Member

- Joined

- Jun 9, 2025

- Posts

- 1

- Reaction score

- 0

- Location

- NC

- First Name

- Christian

- Truck Year

- 1976

- Truck Model

- C10

- Engine Size

- 350

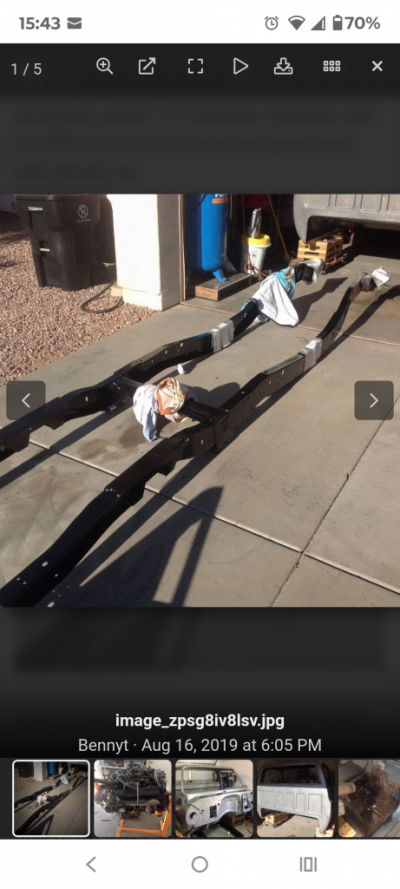

Hello, new to the group but have had the same Squarebody for 30 years. I bought this truck in HS with my Dad and its been off the road for the past 25 years. I started a frame-off a year ago as one section of the frame had irreparable rust damage. I bought a new-to-me frame but I wanted to explore the possibility of swapping the good frame rail in the original frame with the donor frame rail. The benefit would be that it keeps the original VIN stamping and I get to keep a piece of my Dad and I. I understand its a lot of work drilling out rivets and replacing w Grade 8 hardware but is there any alignment that would be lost? Will the original holes line up? One truck was built in Baltimore ('76) the other in Flint ('75). Currently both frames are rolling chassis. I'd be interested in hearing from someone that has actually done or attempted to do this to get their perspective.