I'm seeing this thread kind of late but I want to reiterate a few points. Yea, oil has changed in leaps and bounds and in many ways it's been good. We see very, very few engines with sludge issues, where it use to be common place, I'd say that's the biggest plus to the changes. But zinc levels are wayyyy down. 500 - 800ppm, in the 80's it was 1,200 - 1,500, and don't forget you need a dose of phosphorus with that in similar levels. Why is zinc important? It coats moving parts and acts as part of the lubrication chain, and can take the pressure between the cam and lifter surface without breaking down (or being pushed out)

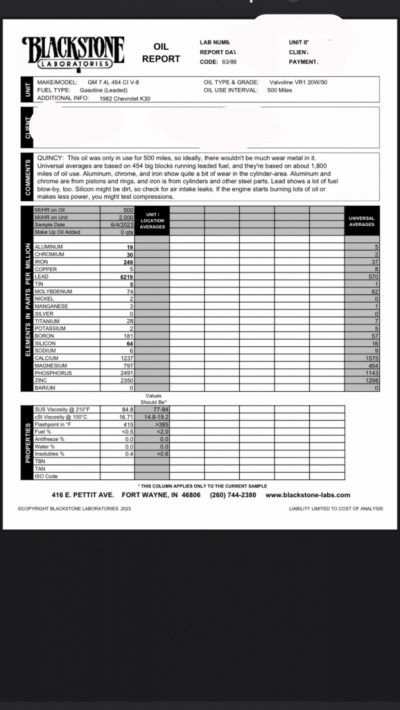

You absolutely HAVE to use a high zinc break in oil on a flat tappet cams and lifts TODAY, in the past there was enough zinc to pour in whatever and get away with it. Lucas break-in oil is great and has NEVER let us down, nor has Valvoline racing oil. Typically I tell guys that have had new motors installed to run the Valvoline oil for at least the first few changes preferably until there is 10K on the motor and the cam and lifters are well seasoned. After that pick what you want, unless it's high lift cam. Most desiel oil is going to be 1,000 - 1,200ppm zinc, great for a little extra protection in an engine used hard, but even though it's probably enough for break-in, once you wipe a cam and lifter or lifters now you have circulated some fine particulate of oil throughout your motor. Will it live though that? probably. Is it extra risk. Yes, high zinc break in oil, and running high zinc for the first few changes is cheap insurance.

Like Rick said and again it is cheap insurance even though you might make a mess, check to make sure those push rods are spinning! No spin also equals cam and lifter failure too.

Now in the case of any lifter that came out like that, the cam has the opposite wear. I'm sorry your not going to be able to see that wear on the cam using a scope. But think about it. If the lifter wears concave the cam literally has to have to opposite wear on it, or the lifter would simply be worn down flat, which it is not.