Blmpkn

Full Access Member

- Joined

- Aug 9, 2021

- Posts

- 57

- Reaction score

- 62

- Location

- Maine

- First Name

- Will

- Truck Year

- 1986

- Truck Model

- 1500

- Engine Size

- 4.3

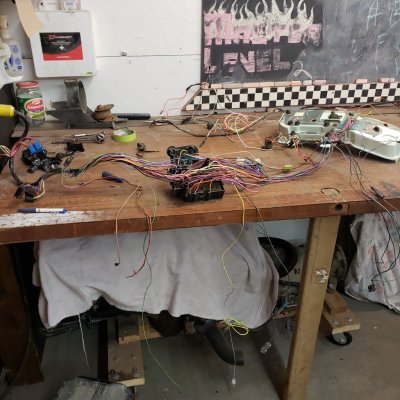

I'm thinking I'd like to make/buy my truck a bare bones wiring harness. Super minimalist. Its a manual door truck, no a/c or cruise or any of that fanciness.

All I want is power to the cab (radio, dome light, blower motor, guage cluster) and the exterior lights.

What's the easiest way to go about this? I hate electrical stuff. I'm convinced it's witchcraft and am near hopeless at ever gaining an understanding of it. If you have a 4 year old daughter, she probably understands this nonsense better than I.

Simpler the better.

All I want is power to the cab (radio, dome light, blower motor, guage cluster) and the exterior lights.

What's the easiest way to go about this? I hate electrical stuff. I'm convinced it's witchcraft and am near hopeless at ever gaining an understanding of it. If you have a 4 year old daughter, she probably understands this nonsense better than I.

Simpler the better.