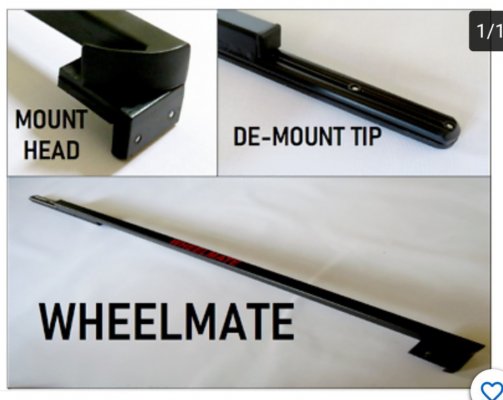

Coates power bar mounted on uni strut works pretty good, when I'm bored some day I'm going to copy the wheelmate/MOJOlever design I think it will work as well as the coates tireman bar. The duck head works very well,just a little more time consuming,take it off put the wheel and tire down,put it back on use it take it off,put another wheel up,repeat. The tireman bar, put your wheel up place your bar,pull,done. Throw on your next wheel. Also had to weld and modify the mounting base,because used the heck out of this 100s if not thousands of tires. I wouldn't buy it again. I'd build it,it would be better and cheaper. Too simple to build just the base and that's the only part of mine that is original,and I had to strengthen it.