You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RETRO-Mod: Jeep intermediate steering shaft

- Thread starter RetroC10Sport

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

- Joined

- Sep 29, 2010

- Posts

- 17,221

- Reaction score

- 2,606

- Location

- Green Bastard Parts Unknown

- First Name

- Jay

- Truck Year

- 2001

- Truck Model

- pontiac aztek

- Engine Size

- 3.4

Because the rag joint gets flaccid again in 6 months.

- Joined

- Feb 5, 2014

- Posts

- 4,612

- Reaction score

- 3,938

- Location

- Kentucky

- First Name

- David

- Truck Year

- 1986

- Truck Model

- K10/LM7 5.3/4L60e/np208/3.73/32"

- Engine Size

- 10 yrs Air Force

I thought both were keyed so I took it off and looked. They both are at the steering gear. So I thought I'm already here why not. I took my dremel tool to the steering shaft off the jeep and ground out the flat portion enough for a tight fit.

I put in on and it was off by 45° so I pulled it back off and repositioned it. The 2nd time it was still a tight fit as I had to use a hammer to tap it on there.

Of course I put silicone on there each time, so I had to clean the excess silicon off because it came out the other end LOL.

Thanks for the quick replay Val

If I had to do it again, I WOULD NOT PULL OUT THE DREMEL!!! Do it correctly and have the end of the shaft turned to fit as a few have posted. I'm not sure if the bolt wasn't tight enough to begin with or what. If a cop had got behind me the past 2 days I'd been pulled over for suspected DUI....let alone the safety factor. I've seen worse in wheel play, but it wasn't fun for sure.

While under the gear box, I grabbed the shaft and rotated back a forth and watched the post it connects to. I had slippage. Tightened up the bolt and everything is fine...for now.

ADMIN: I'm not sure if we want to leave my previous post in as a lesson learned or just delete it all together. Up to you all, lol I'm not responsible for any damages!!!! At least put flags on it waving don't do this or something please.

1low4x4

Full Access Member

- Joined

- Feb 14, 2011

- Posts

- 2,512

- Reaction score

- 906

- Location

- Texas

- First Name

- Nick

- Truck Year

- 1984

- Truck Model

- K10

- Engine Size

- 5.7

so is this still an effective and safe modification for these trucks? I saw something about tack welding, and inserting bolts into the smaller and bigger shaft. I don't want to do something that will be half ass and could possibly fail

Skweegle89

Full Access Member

- Joined

- May 21, 2014

- Posts

- 2,347

- Reaction score

- 26

- Location

- Oklahoma

- First Name

- Zach

- Truck Year

- 1985

- Truck Model

- K10

- Engine Size

- 350

Any of you guys have these Cherokee steering shafts for sale?

X2

Sent from an old rotary telephone.

beest

Full Access Member

- Joined

- Feb 13, 2015

- Posts

- 109

- Reaction score

- 29

- Location

- indiana

- First Name

- matt

- Truck Year

- 84

- Truck Model

- k10

- Engine Size

- 350

Just a small update for the folks looking to do this mod, you want the shaft out of the older square body style xj. The newer xj has splines on both ends. The jeeps look almost identical. But the newer ones will not work on your square body. Your looking for the ones that both ends of the shaft are under the hood. I didn't see that in this thread, and when I got a shaft at my local pic-a-part yesterday the one that I got was incorrect. Just thought I'd post up and save someone a return trip to the yard.

Evans Ward

Member

- Joined

- Mar 15, 2015

- Posts

- 32

- Reaction score

- 19

- Location

- GA

- First Name

- Evans

- Truck Year

- 1987

- Truck Model

- Sierra Classic 1500

- Engine Size

- 350

I bought one off ebay at an affordable price. After I installed it, I noticed the end of the shaft coming from firewall direction has a lot of play. Does that mean that it needs tightening from inside the cab/ column area deep inside the internal workings?

- Joined

- Aug 29, 2010

- Posts

- 47,306

- Reaction score

- 9,672

- Location

- OKC, OK

- First Name

- HotRod

- Truck Year

- 85 K20 LWB

- Truck Model

- Silverado

- Engine Size

- 454 - Turbo 400 - 3.73

Just a small update for the folks looking to do this mod, you want the shaft out of the older square body style xj. The newer xj has splines on both ends. The jeeps look almost identical. But the newer ones will not work on your square body. Your looking for the ones that both ends of the shaft are under the hood. I didn't see that in this thread, and when I got a shaft at my local pic-a-part yesterday the one that I got was incorrect. Just thought I'd post up and save someone a return trip to the yard.

Very good point to revisit. In post #1 it does mention from a 1988-1996 model Jeep Cherokee. As you mentioned, the later models WILL NOT work.

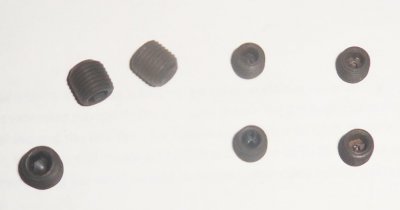

Here is the picture of what the model we need looks like.

- Joined

- Feb 5, 2014

- Posts

- 4,612

- Reaction score

- 3,938

- Location

- Kentucky

- First Name

- David

- Truck Year

- 1986

- Truck Model

- K10/LM7 5.3/4L60e/np208/3.73/32"

- Engine Size

- 10 yrs Air Force

Again thanks for this post, I'll be doing it again.....without the dremel this time LOL. Went to a HS graduation in TN and stopped by a PAP and got 2 off in 20 minutes. I'm getting faster at this one LOL.

Cinci price was $14 total. TN price was $15 for the 2...can't beat that.

Update: Man the smell set my nose on fire. Dummy me didn't do it outside the garage on the first. Both are apart after about a minute with a small torch for household piping. Vice grips on one end and smack it on something solid a bit. You'll see the progress from each when it's loose enough.

Also, one has the play that Kapdin shows on the upper joint (page 6 of this thread). I'll have it welded.

Cinci price was $14 total. TN price was $15 for the 2...can't beat that.

Update: Man the smell set my nose on fire. Dummy me didn't do it outside the garage on the first. Both are apart after about a minute with a small torch for household piping. Vice grips on one end and smack it on something solid a bit. You'll see the progress from each when it's loose enough.

Also, one has the play that Kapdin shows on the upper joint (page 6 of this thread). I'll have it welded.

Last edited:

- Joined

- Feb 5, 2014

- Posts

- 4,612

- Reaction score

- 3,938

- Location

- Kentucky

- First Name

- David

- Truck Year

- 1986

- Truck Model

- K10/LM7 5.3/4L60e/np208/3.73/32"

- Engine Size

- 10 yrs Air Force

Val I finally got the wheel straight with this new shaft. It's exactly like you said, to a point. With both the box and shaft being keyed, I thought I would end up taking it somewhere to get it turned 90°'s.

It wouldn't go on with it turned, even with some tapping (Happy Gilmor). I almost gave up. Then I turned it 180°'s from that position and tap-tap-tappy got it right on there.

LOL glad I figured this one out cuz it's been buggin me since you replied last year. Not that I was thinking you were wrong, just what am I missing.

It wouldn't go on with it turned, even with some tapping (Happy Gilmor). I almost gave up. Then I turned it 180°'s from that position and tap-tap-tappy got it right on there.

LOL glad I figured this one out cuz it's been buggin me since you replied last year. Not that I was thinking you were wrong, just what am I missing.

- Joined

- Feb 5, 2014

- Posts

- 4,612

- Reaction score

- 3,938

- Location

- Kentucky

- First Name

- David

- Truck Year

- 1986

- Truck Model

- K10/LM7 5.3/4L60e/np208/3.73/32"

- Engine Size

- 10 yrs Air Force

I've got it secure to my liking now. I drilled holes to run a bolt through both parts, like the GM shaft had. I figured why not, I've got 3 good upper parts to play with. My hole was off center so I used a file to get them lined up. Wasn't off by much, maybe an 1/8".

Between the silicon, the Jeep bolt, and the bolt going through both parts......I don't think it's coming off LOL.

Too much?

Between the silicon, the Jeep bolt, and the bolt going through both parts......I don't think it's coming off LOL.

Too much?

- Joined

- Aug 29, 2010

- Posts

- 47,306

- Reaction score

- 9,672

- Location

- OKC, OK

- First Name

- HotRod

- Truck Year

- 85 K20 LWB

- Truck Model

- Silverado

- Engine Size

- 454 - Turbo 400 - 3.73

I think you did just fine. You've still got the vibration dampner feature in tact, as well as the break away feature for the 2 separate pieces. I call it good.

On mine, what I've decided I'm going to do as far as the 2 shafts, I found these set screw things in one of my parts organizer trays with my light bulbs and fuses. I'm going to drill 2 holes on the outer piece and tap some threads into the drilled holes. After I install the shaft, then I'll use some Loc-tite Blue (hand tool strength) and snug the set screws. That should be just enough to hold the 2 pcs tight, but yet still be able to slip and break away in a collision.

On mine, what I've decided I'm going to do as far as the 2 shafts, I found these set screw things in one of my parts organizer trays with my light bulbs and fuses. I'm going to drill 2 holes on the outer piece and tap some threads into the drilled holes. After I install the shaft, then I'll use some Loc-tite Blue (hand tool strength) and snug the set screws. That should be just enough to hold the 2 pcs tight, but yet still be able to slip and break away in a collision.

Attachments

firebane

Full Access Member

- Joined

- Jul 10, 2014

- Posts

- 1,732

- Reaction score

- 31

- Location

- Calgary, AB

- First Name

- Curtis

- Truck Year

- 1974

- Truck Model

- K10

- Engine Size

- 350

If I can get a hold of one of these I'm going to try and see what it would take to make it work on my 74 without swapping steering boxes.

Similar threads

- Replies

- 10

- Views

- 1K

- Replies

- 2

- Views

- 212

- Replies

- 3

- Views

- 292

- Replies

- 1

- Views

- 219