OK, MO, here's the science.

At idle, let's say you are running 16 inches of vacuum. That's half an atmosphere coming in the intake, right? So if you have a stock 350 with 8:1 compression, you only get up to 4 atmospheres of cylinder pressure. This is a thin mixture, and burns slowly. Therefore, you need more advance to have the combustion pressure max out at the right point for pushing on the piston.

Now you open the throttle, and the intake goes to one atmosphere. Now your 8:1 compression can get up to 8 atmospheres of pressure in the cylinder. This thicker mixture burns much faster, so you need to ignite later to get the pressure pulse to hit the piston at the right time.

That is, the vacuum advance is to give extra time to thin mixtures to burn. The rationalizations I see for ported vacuum (as above) never mention the combustion chemistry: thinner mixtures burn more slowly, they need more time.

Centrifugal advance is because the time it takes for the mixture to burn is in fractions of seconds, but the ignition timing is set in degrees. The same number of degrees is a shorter time in seconds when the engine is spinning faster, so the spark needs to be advanced in degrees to give the same seconds for the mixture to burn.

Early vehicles had mechanical advance on the steering wheel, like a turn signal lever. In 1930, Studebaker introduced the vacuum advance to use the measure of how thin the mixture was (the intake manifold vacuum) to advance the timing to give the thin mixture time to burn. It was not needed when the throttle plate was open and the mixture was thicker. This mechanical advance was connected to manifold vacuum, and all vacuum advance modules on production vehicles from 1930 through 1967 were connected to manifold vacuum, because that is the direct measurement of what the cylinder pressure will be when ignition occurs.

On January 1, 1968, new emissions standards came into law. These standards included a measurement of unburned hydrocarbons at idle. Two reasons for that: 1) it was easy to measure when people came in to get their cars tested, because they could just idle there and you stuck the sensor up the tailpipe and measured it, and 2) because unburned hydrocarbons were a big issue in cities that had a lot of traffic jams (people idling) and the resulting smog, which was a huge health issue.

The solution was to pump air into the exhaust manifolds with an AIR pump, to give these unburned hydrocarbons oxygen to burn with, and to switch the idle timing to ported vacuum. This was still the direct measurement of engine cylinder pressure at all throttle openings except at idle, but at idle it was late (lack of advance to accommodate the thinner mixture). The result was that the charge was still burning when the exhaust valve opened, releasing the burning charge into the exhaust manifold where the combination of unburned hydrocarbons, injected air, and a burning charge could continue the combustion process and reduce unburned hydrocarbons. The higher exhaust temperatures also helped primitive early catalytic converters reach their required operating temperature.

It also resulted in higher engine temperatures (because the charge was still burning when it passed out through the exhaust runners in the head), a rough idle, and an off-idle hesitation when the throttle was opened until the vacuum advance caught up to where it would have been if it had been monitoring the manifold vacuum, and therefore the cylinder pressure. Lots of accommodations in base timing and mixture were made to make this work, more or less.

I was 15 years old, car crazy, and working in a machine shop when all this happened in 1968/1969. It was in all the car mags at the time. Some of the guys buying new cars were disgusted with the performance. They machined off the impeller vanes inside the AIR pumps and ran on manifold vacuum. They just had to switch to ported vacuum to pass visual inspection. Actual tailpipe inspection didn't take place where I lived. Most people now don't put AIR pumps on their period cars and trucks when they fix them up, but somehow ported vacuum hung on.

But the old-timers who were around back in the day know all this. For example, the documentation for the Edelbrock 1406 notes that the ported vacuum port is to be used for vacuum advance on emissions-equipped engines, and the manifold vacuum port is to be used for vacuum advance on non-emissions-equipped engines.

One other note. A rich mixture also burns faster than a lean one. If you set the idle mixture on a vehicle with an A/FR meter -- say to 13.5:1 because a thin mixture carbureted at low stack velocity isn't uniform and any cylinder getting over 17:1 won't light -- then switching from ported to manifold vacuum will be a huge difference for the positive.

However, one method for setting idle mixture that I have seen a lot is to adjust for maximum vacuum. On manifold vacuum, this will get you to about the right mixture. But if you are hooked to ported vacuum, and you adjust the idle mixture for maximum vacuum, you will be setting the mixture much richer than 13.5:1. The richer mixture burns faster than the correct mixture, partially making up for the late spark. So it masks some of the negative effects of ported vacuum. Switching this rich idle mixture over to manifold vacuum may idle worse than on ported, but it's a combination of errors.

Thus my one-liner on the other thread that if the other poster's truck ran better on ported than manifold vacuum, he didn't know how to tune a carburetor. Maximum performance will be achieved with proper tuning on manifold vacuum. It is the best indicator of dynamic cylinder pressure at ignition, and how much time the charge needs to burn optimally. That's why manufacturers used manifold vacuum from 1930 through 1967.

I put this link up a lot, but I'm not sure anyone reads it. It's from the Corvette forums, and is an explanation of ignition timing written by a retired GM ignition systems engineer. It's a good read, and covers this whole thing pretty well.

http://www.corvetteactioncenter.com...ported-vs-manifold-source-vacuum-advance.html

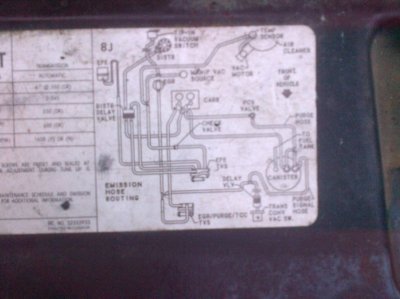

And here's the Edelbrock diagram I mentioned.

You must be registered for see images attach

What was it you were wanting from me???

What was it you were wanting from me???

But, I"ll always use ported vacuum and those who see different and more than welcome to hook to manifold vac. I'm not going to knock anyone for hooking it how they wish. It just makes a good topic argument for gearheads.

But, I"ll always use ported vacuum and those who see different and more than welcome to hook to manifold vac. I'm not going to knock anyone for hooking it how they wish. It just makes a good topic argument for gearheads.