chief_shotts

Member

- Joined

- Nov 29, 2021

- Posts

- 33

- Reaction score

- 33

- Location

- beaverton, OR

- First Name

- edgar

- Truck Year

- 1986

- Truck Model

- k30

- Engine Size

- 383

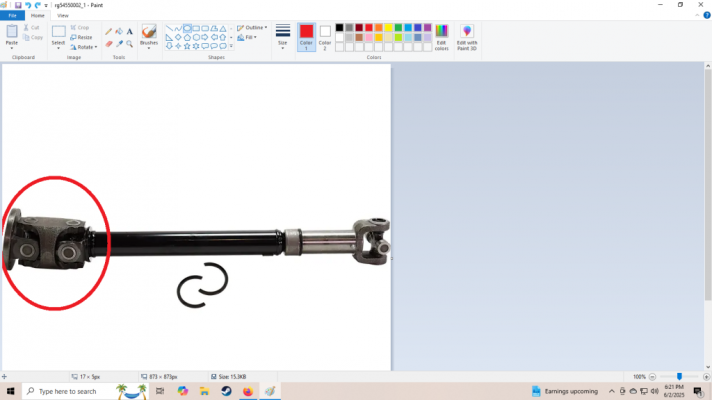

I am curious what other square owners do to remedy harsh front driveline angles when lifting their truck.

My truck has a 6in lift, Dana 60, and np 205 tcase. The driveline angle is roughly 19 deg down, The t case is sitting at about 6 deg up, and the pinion is about 5.5deg down. Given these numbers the joint at my transfer case has an operating angle of 24.5 degrees.

Currently the front drive is unusable due to vibration from the driveshaft. Any advice from those who have a lifted truck would be appreciated.

My truck has a 6in lift, Dana 60, and np 205 tcase. The driveline angle is roughly 19 deg down, The t case is sitting at about 6 deg up, and the pinion is about 5.5deg down. Given these numbers the joint at my transfer case has an operating angle of 24.5 degrees.

Currently the front drive is unusable due to vibration from the driveshaft. Any advice from those who have a lifted truck would be appreciated.