305_Square_Body

Member

- Joined

- Mar 27, 2023

- Posts

- 35

- Reaction score

- 10

- Location

- Richmond, VA

- First Name

- Andrew

- Truck Year

- 1987

- Truck Model

- R10

- Engine Size

- 305

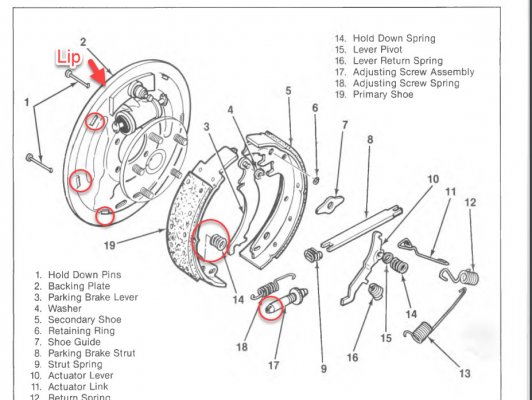

What's up square body friends? So, I have been enjoying myself doing my first drum brake job on my 87 R10. I have found amazing videos on Youtube and I'm about 90% there but that 10% is driving me nuts. A few things eating at me.....

1) Do the shoes sit deep in the lip of the backing plate or do they need to come out from that and rest on those contact points? In my mind, if they sit in the lip, they will not expand out and contact the drum and/or the lip will carve a groove in the shoes.

2) I am having trouble getting my old pins to go all the way into the brake cylinder so they are just kind of hanging there while I try to install the shoes. Is that due to pressure? Is there a way to relieve it so the pins go all the way in? Will it just sort itself out with use?

3) I have installed those two pins that you push through the back of the backing plate and hold down with springs. The one on the right seems nice and snug but the one on the left doesn't seem quite as tight. Same pin, same spring. What could I be doing wrong there?

4) I also want to replace all the brake fluid in the process. Is it true that I shouldn't let the master cylinder go completely dry in the process?

5) In part 17, is there a trick to getting that circled part to screw out?

1) Do the shoes sit deep in the lip of the backing plate or do they need to come out from that and rest on those contact points? In my mind, if they sit in the lip, they will not expand out and contact the drum and/or the lip will carve a groove in the shoes.

2) I am having trouble getting my old pins to go all the way into the brake cylinder so they are just kind of hanging there while I try to install the shoes. Is that due to pressure? Is there a way to relieve it so the pins go all the way in? Will it just sort itself out with use?

3) I have installed those two pins that you push through the back of the backing plate and hold down with springs. The one on the right seems nice and snug but the one on the left doesn't seem quite as tight. Same pin, same spring. What could I be doing wrong there?

4) I also want to replace all the brake fluid in the process. Is it true that I shouldn't let the master cylinder go completely dry in the process?

5) In part 17, is there a trick to getting that circled part to screw out?