Dieseladdiction

Junior Member

- Joined

- Apr 10, 2014

- Posts

- 10

- Reaction score

- 0

- Location

- Celina,tx

- First Name

- Michael

- Truck Year

- 1979

- Truck Model

- K10

- Engine Size

- 350

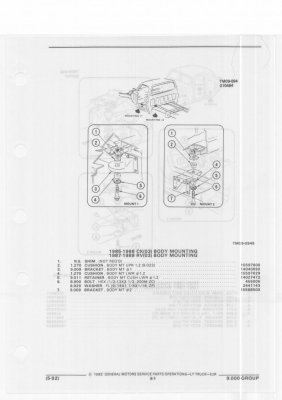

Hey guys, new to the forum. I picked up a 1979 chevy k10 4x4 and I'm replacing the body bushings. I've done this before on my 1977 I used to have but I don't remember this, anyways I'm trying to remove the cab bolts closest to the bed and one side is loose and just spins and the other side is really tight. My question is, is the nut suppose to be welded and it just broke? If so how can I go about removing it? Thanks