deucecoupe

Junior Member

- Joined

- Jun 29, 2022

- Posts

- 17

- Reaction score

- 9

- Location

- Lake Oswego OR

- First Name

- Richard

- Truck Year

- 1984

- Truck Model

- C10

- Engine Size

- 350

I'm a little late to this thread. I'm doing a 250 to 327 swap right now into my '84 C10.

When I pulled off the old motor mounts on the front crossmember, there were two sets of holes - one set lower and one set slightly higher but neither forward or backward. The 250 lower sat in the lower set of holes.

I just mounted the new SBC motor mounts into the upper holes and everything is fine.

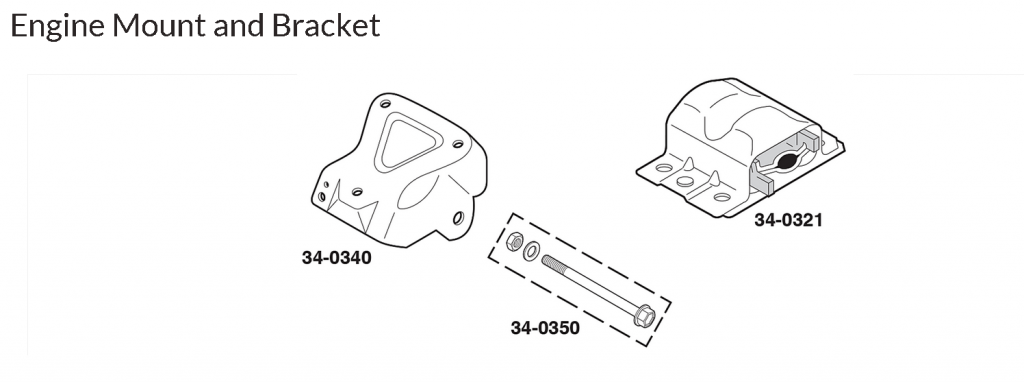

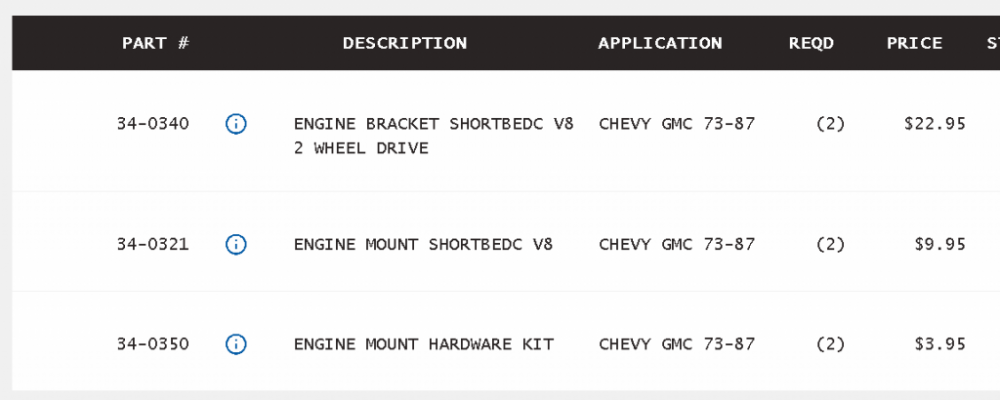

The pics from Bextreme04 were exactly what I used. The lower mounts are easy to find and purchase. I dug around on FB marketplace and craigslist to find a used set of the upper clamshells that worked perfectly. Just need paint.

This isn't a hard swap to do, but I've spent more time than I thought finding all the various brackets and pulleys.

Good luck

When I pulled off the old motor mounts on the front crossmember, there were two sets of holes - one set lower and one set slightly higher but neither forward or backward. The 250 lower sat in the lower set of holes.

I just mounted the new SBC motor mounts into the upper holes and everything is fine.

The pics from Bextreme04 were exactly what I used. The lower mounts are easy to find and purchase. I dug around on FB marketplace and craigslist to find a used set of the upper clamshells that worked perfectly. Just need paint.

This isn't a hard swap to do, but I've spent more time than I thought finding all the various brackets and pulleys.

Good luck