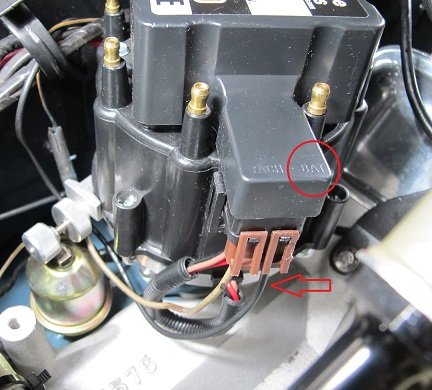

IMPORTANT, regarding using the BAT connection at the distributor:

FIRST, many warn against using the distributor tap for power, citing that using the battery terminal of the distributor can starve it of power needed for a top performing engine.

This makes sense in that it’s indicated the choke requires a 20 amp circuit and will be operating the entire time the rig is running. The battery terminal on a distributor only has to provide enough power to create an arc on one spark plug at a time.

Back in the day, my old truck saw 7 amps at the stock points. I changed to capacitive discharge to drop the point amperage from 7 amps down to 2/10 of an amp, or 200 milliamps, to make the points last FAR longer.

SIDE NOTE: They lasted so long the rider lobe finally started causing the dwell setting to drop off to almost closed every couple days. At first, I thought the problem was, I hadn’t tightened the points well, but figured out it was something else when I made sure I did, and it happened a couple days later.

SOME Net searches indicate the distributor-coil only need about 3-5 amps to operate effectively. That means the stock wire there may well be too undersized to use as a tap source.

OTHER Net searches indicate HEI systems can use as much as 30 amps.

In accordance with the foregoing, it is likely the wire feeding the battery terminal of the distributor would need to be increased in size, if it is going to be tapped for choke operation.

If, for example, you had HEI ignition taking 30 amps, adding the 20 choke means you’d need a 6 gauge wire to handle the 50 amps drawn on the circuit by the distributor and choke.

For stock wire systems, that means replacing the wire between the distributor and the starter solenoid having 12 volts only with the ignition on with a larger wire.

SECOND, if your distributor voltage DROPS FROM 12 volts to, for example, 7 volts, as many systems do when you go from start to run, the key run position feeds the distributor via a ballast resistor, or resistance wire, so you WILL NOT get the full 12 volts the choke requires.

THIRD, just to be, electronically speaking, safe, if using a sending unit, the same applies - it should be verified the sending unit feed wire can handle the 20 amps the choke requires, and still provide power to the sender, for the gauge or light operation.

SIDE NOTES

For my 78, going to a larger gauge is less a problem. With headers, there is the matter of getting your hot wires past them, to and from the starter, without them being affected by the high temperatures. One way of lessening the problem is, fewer wires.

Since the hot to the starter solenoid is being used as a power buss bar for other circuits requiring battery power, circuits merely tapping battery power off the solenoid (e.g., fuse block power) can be moved to after market power access point, or points, at locations well above and away from the headers, that are more convenient to access and are otherwise no a potential hazard to the wires.

Circuit protection is still a must.