jgasca

Full Access Member

- Joined

- Jun 28, 2012

- Posts

- 174

- Reaction score

- 1

- Location

- New Mexico

- First Name

- Jose

- Truck Year

- 1985

- Truck Model

- k1500

- Engine Size

- 350

For some reason, I'm thinking if he has no fuses in the ECM or ECMB, then he has no ECM or ALDL. Does ESC alone have an ALDL? He may just have an ESC only truck? I don't recall any of my 85's having an ALDL and I have 3 and had 6 85 and up.

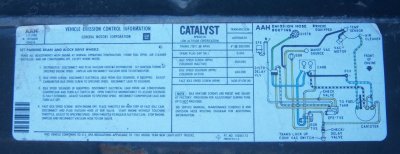

Well I'm not familiar with an ESC, Electronic Stability Control I'm guessing, but here's a pic of whats under the pass dash;

You must be registered for see images attach

I'll be trying another oil pressure switch tomorrow, if that doesn't work, i'm not sure what will