Ricko1966

Full Access Member

- Joined

- Apr 11, 2017

- Posts

- 6,678

- Reaction score

- 11,408

- Location

- kansas

- First Name

- Rick

- Truck Year

- 1975

- Truck Model

- c20

- Engine Size

- 350

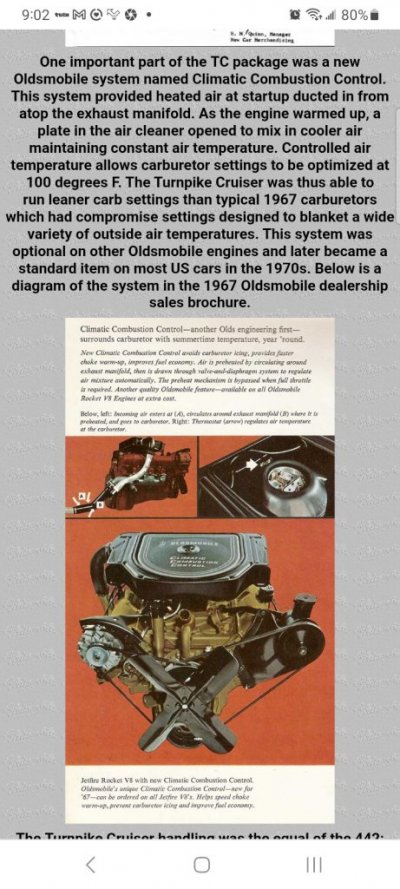

1967 Oldsmobile Turnpike Cruiser. 20 MPG 400 CID Cutlass.Electronic ignition,Temperature controlled air cleaner,highway gears. Check out that distributor and air cleaner, looks kinda familiar,doesn't it?

You must be registered for see images attach

You must be registered for see images attach

Attachments

Last edited: