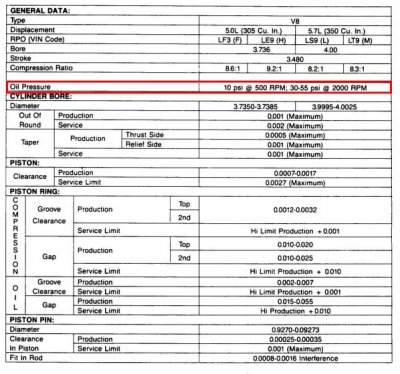

@theblindchicken: I think you should stop betting on scenarios and attach a mechanical gauge. The oil pickup space-to-pan isn't going to affect your oil pressure with a full capacity of oil in the pan. Moving from one oil filter (of quality) to the next filter (of quality) isn't going to affect your pressure.

You're engine is either making correct pressure, or it isn't. Find out with a mechanical gauge.

If it isn't making pressure, the pump is either worn out, the check valve for the pressure relief is leaking, or the bearings for the crank, rod, or cam are worn out. That's it.

You can check the crank and rod bearings with the pan removed, and while there, replace the pump. I believe there are high pressure versions available, as well as high volume versions. So in this part of your diagnostics (should the mechanical gauge show low pressure) if the crank/rod bearings are good, and you replace the pump, if you still have low pressure once back together, you can probably assume the cam bearings are bad.

Using the aftermarket mechanical gauge prior to it breaking, it read very similar pressures to the OEM gauge (34psi cold start) while having a small leak at the gauge fitting.

The truck & engine have a total of 80-82k original miles. Approximately 20-30k miles on the engine after a full rebuild even though that was back in the 80's by Joe Reath when his shop was still located on Cherry Avenue in Long Beach, CA.

I feel it is very unlikely that the pressure drop has anything to do with these bearings because the drop only occurred after the following took place:

1. Oil pan was removed

2. Oil pan gasket was removed & replaced

3. Old Fram PH5 was replaced with another Fram PH5

4. Everything was reinstalled

Low pressure was noticed, took everyone's advice and replaced with a quality filter: K&N HP-3002

Prior to the pan removal and parts replacement, the truck idled at a comfortable 45psi cold / 30 psi warm, in gear. The oil pressure responds accordingly when the throttle is increased like it should. Thus, my belief is that the issue is not with the bearings or the oil pump at all, but it was completely with the fact that it was oil and the filter that hadn't been changed in quite a while.

I do not remember the last time the oil filter was changed. The oil was last fully changed at the same time as the filter. I just always made sure the oil was topped off. Thus, if, as Chegny mentioned, the oil filter was damaged due to age and was no longer actually filtering correctly, the pressure may have been higher compared to an oil filter that is actually filtering.

It seems unlikely that the pump is worn out, but parts do sometimes prematurely wear out when compared to their engineered lifespan.

As for the check valve, this is located in the oil pump, correct? Is there a way to test that it is leaking under pressure compared to having oil just being splashed onto it?

Now, I would like to have another mechanical gauge to correctly tell me the current pressures. What aftermarket gauge would any of you recommend that doesn't break the bank? Full sweep would be preferable due to their easier readings.