Servicing the HEI

Due to its trouble-free nature, the HEI is an often-neglected component. Since it is electronic, many people seem to believe that if it is working, all must be well. That may be the case, but once a problem does occur, it is important to be able to diagnose it. By following the steps in this primer, you will be able to accurately diagnose and repair any GM HEI system. We traveled to Classic Restoration Enterprises in Pine Island, New York, where technician Richard Wiegand worked with us using a brand-new ACCEL HEI unit to illustrate the inner workings of the HEI and how to service it.

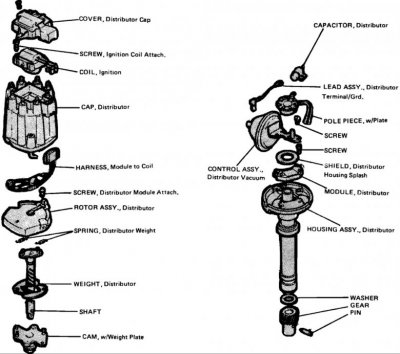

There are three main components in an HEI: the ignition module, the pick-up coil and the integral high-tension coil. The other components of the distributor, such as the mechanical and vacuum advance, gear drive and shaft, are all very similar in function to those found on a breaker-point system. Comparing the HEI components to those in a conventional distributor makes it easier to understand and repair.

The ignition module can be thought of as the contacts of the breaker points, while the pick-up coil and reluctor (the tooth wheel on the distributor shaft) serves the same function as the distributor cam and rubbing block. Thus, for the module to charge and then collapse the coil, it needs to receive a signal from the pick-up coil. The output of the pick-up coil is identified as a saw-tooth sine wave and can be confirmed with a voltmeter.

You cannot check the module itself internally, so the diagnostic steps required generally involve confirming operation of everything else: If the other parts test fine, replace the module. Often, the diagnostic steps are skipped and the person working on the car assumes the module has failed, using parts replacement as a diagnostic procedure. The diagnostic steps allow you to avoid this practice.

Check the dwell on an HEI module to confirm the circuit is evoking the longer (expanding) dwell time as the engine speed is increased. To do this, connect a tune-up tach and dwell meter to the "TACH" terminal on the distributor cap and then start the engine. At idle on a V-8, the dwell with a Delco module should be between 10 and 15 degrees. As the engine speed is raised, the dwell should increase to 30 to 35 degrees by 2,500 rpm. If it does, the module is working properly.

Note that some aftermarket ignition modules do not provide the proper expansion of dwell: They often have an excessive amount at idle and provide little increase at high speeds. This can cause a misfire at high rpm, because the coil saturation is not sufficient. Conversely, if the dwell sticks on the module, the engine can exhibit a very rough idle with a dead misfire, hesitation at light load, pinging and overall poor performance. If the dwell period is incorrect, the diagnosis is simple: Replace the module.

The only time a properly working HEI module will show a fixed dwell of around 30 degrees is if an aftermarket CD ignition box, like an MSD or similar unit, is attached. The current draw of the CD unit will drive the module to a dwell period that is similar to that at high engine speeds in a stock application.

Ignition system design is still evolving today with distributor-less and coil-on-plug systems. With every new theory, the same basic premise still applies: Widen the gap of the spark plug to increase the ionization window and keep the plug arced for as long in the crankshaft's rotation as possible. Though no production version of the original HEI system is in use today, it was clearly a design that revolutionized the industry and laid the groundwork for today's modern ignition systems.

NOTE CORRESPONDING IMAGES ARE BELOW THE TEXT

The original HEI design featured an integral ignition coil and a one-wire hook-up of 12 volts. The cap is marked to identify the tach and voltage supply.

You must be registered for see images attach

The wide spacing of the secondary terminals in the cap was necessary to prevent cross-fire between cylinders and to eliminate arc-over to ground. This was due to the high output.

You must be registered for see images attach

The coil is retained by four screws. It is important to make sure the screws are the proper length and do not puncture the distributor cap above the rotor. The ground strap under the coil, which is used to bleed off any electrical charge that may accumulate in the coil's metal support frame, needs to be replaced.

You must be registered for see images attach

Once the coil is removed, the carbon button can be accessed. When installing a new cap, do not forget to install the new carbon button. Many leave the button out and the coil arcs to the rotor through the hole. The engine will start this way, but will misfire in a few miles.

You must be registered for see images attach

You must be registered for see images attach

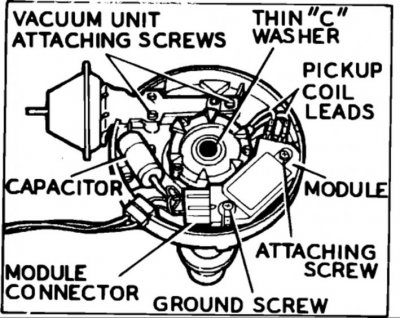

This is what you will see with the cap and rotor removed. The vacuum advance connects to the pick-up coil; those leads have a tendency to break from movement. This usually causes the engine to sputter, backfire and possibly stall at light load, though it will run fine at idle or full throttle. If this occurs, a quick diagnostic step is to disconnect the vacuum line so the advance does not function to see how the engine runs. The condenser is used for radio noise suppression.

You must be registered for see images attach

To remove the distributor advance weights, the springs need to be taken off their moorings by pulling and lifting up.

You must be registered for see images attach

You must be registered for see images attach

To remove the module, the leads from the pick-up coil need to be disconnected. Be gentle with the wires, especially with an older distributor.

You must be registered for see images attach

Once the screws are detached, the module can be removed. The underside should be coated with white grease, which is a heat-sink compound. When the compound gets old, it will become hard and ineffective in transferring heat. The result will be the loss of ignition at high temperature, as the module overheats.

You must be registered for see images attach

The module attaches to the heat sink and the compound helps transfer heat to the casting.

You must be registered for see images attach

Always wipe off the old compound from the heat sink and module and apply a generous amount of new product. Make sure the product you use is listed as a heat transfer agent and not just dielectric grease. The tube should say "for use under ignition modules." To check the pick-up coil, attach an ohmmeter to the two leads, as seen in the lead photo of this article. The reading should be between 500 and 1,500 ohms. Make sure to jiggle the wires with the meter attached to test for any breaks.

You must be registered for see images attach

To service the pick-up coil, the distributor shaft needs to be removed. The first step is to knock out the roll pin that holds the distributor gear.

You must be registered for see images attach

On an older distributor, you may need to soak the shaft and bushing with a product such as WD-40 to loosen any oil crud that would stop the shaft from lifting up.

You must be registered for see images attach

The shaft should pull straight out of the case. Be patient with the WD-40. If you drive the shaft out with a hammer and block of wood, you may pull the top bushing out of the case. Then you will need to buy a new distributor, because the bushing will likely spin if reinstalled.

You must be registered for see images attach

The pick-up coil is held in place by a blind snap-ring. Often, two picks work better to remove it than snap-ring pliers. Do not lose the clip, because some brands of pick-up coil do not include another one. The attachment to the vacuum advance is clearly seen in this image.

You must be registered for see images attach