Money is so tight everywhere Doppleganger.

Can you think of a way to mod a pair of hard lines or using the old fittings with slight flares to hold the ring crimps from sliding off?

For your aplication, your max pressure is only 150 (+- 40% burst over pressure = 210 psi?)

That's not high pressure.

You can slightly flare the aluminum or copper tubing, either sticking out of the fittings using the old connectors, or by cutting off the factory hydraulic crimp ferrule. In fact, you might be able to source some ruined lines for the connectors you need to save even more money, rather than buy them new. Your hose guy will have damaged lines you can salvage? Let him know it's for a spay gun compressor, not a hydraulic line.

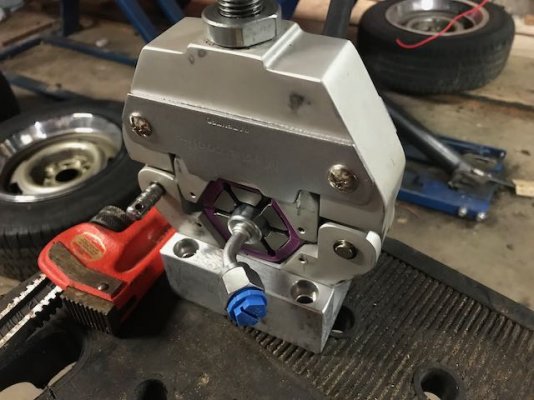

The ferule is the portion that crimps to the hose over the fitting tube, as in my picture above.

The ferule is not connected, usually, but somethimes they are machined from billet.

With a rotory tool or a pair of side cutters you can mangle or disect the ferule from the fitting.

Then use something to very mildly stretch the tubing end of the fitting or copper pipe, force it on, the ring clamps should not slip off under low pressure.

Just stretch the tubing a few millimeters as a snag for the rings to resist the slipage.

Use 2-3 ring crimps over the hose connections, with a slight flare to rubber hose.

Check out this thread where I mention some ring crimps and the tools to make quality low pressure crimps:

https://www.gmsquarebody.com/threads/fuel-hose-ok.42261/page-3#post-895543

Without pictures of the manifold, cooling rack and the fittings you are trying to use, it makes it tough to imagine.

I'm glad it's not high pressure use, because now you can make it work a lot cheaper.

Air compressor is a lot less potiential for getting hurt than 1500-2300 psi hydraulics unit lines.