Bought this truck with Non working A/C system. There was no belt for the compressor, but have since bought one. I need to diagnose the system, and thought I would hook up the belt and see what happens. All stock components presently. A/C compressors turns freely. I want to do this so, 1) see if the compressor clutch works. 2) see if the system will blow some cold air. From there I can start diagnosing the system. Is this the right procedure? School me.

Many times people remove the belt to get better fuel mileage, especially if they never use the A/C.

I would:

Put belt on, and then turn the controls to max A/C (engine running).

If the compressor "clicks" on and continues to run, then the system is fine and you are good to go.

If it doesn't kick on, check to see if you have 12+ at the wire connected near the front of the compressor (near the pump clutch).

If it has power there, but the pump clutch doesn't engage then you need to adjust the pump clutch clearance.

If there is no power there, then you probably have low pressure in the system.

The power to the system goes basically like this:

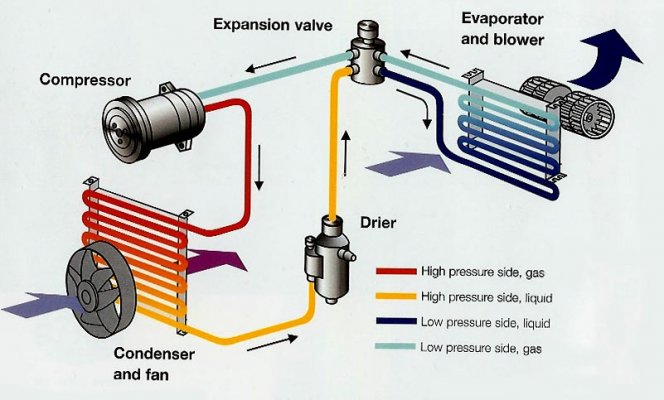

Power to dash switch, to low pressure switch to high pressure switch, to the electromagnet on the compressor. If the pressure is too low, then power won't make it past that switch. If the pressure is too high then the power wont make it past that switch. So if the switch is on, and the pressure is in the correct range, and the pump clutch is adjusted properly and in good working order, then you have good working A/C.

As a test on the pump (compressor), you can run a jumper wire from the + battery terminal to the terminal on the pump.

Warning: DO NOT run your A/C system with a jumper wire for regular use. This is only a test to see if the pump will kick on and rotate. Bypassing the pressure switches can cause damage to the system due to low coolant/oil, or even worse you can over pressure the system and cause a high pressure leak that could spray Freon and a find mist of oil into the engine bay that could ignite. (the oil burns, not the Freon)

As for recharging the system, every area has its own laws and regulations. You may be able to buy R134A Freon in your area in small cans, or you may not. But you can't buy R12 at any store in the USA. Some people cross a border into another state or country to buy Freon, and other people buy it private party on Craigslist or FB Marketplace. Refilling the system is very easy. Takes about 10 minutes and is just slightly more complicated than airing up a tire. Done it successfully many times on all different kinds of vehicles with R12 and 134A. The cost to refill the system is $10 to $30 depending on where you get the Freon and oil. The refill hose usually comes with the can, but if it doesn't - its maybe $5 to $10 on Amazon.

Some people will certainly disagree with everything I said. They will say that you need to have the system professionally inspected, have the system purged with special equipment to get all the air and moisture out of the system, use special equipment to measure the hi pressure side and low pressure side simultaneously while filling the system, add the exact amount of coolant and oil, etc etc (very expensive).

Only you can decide what the best direction to go is.