You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

steering box adjustment

- Thread starter dieselade

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Redfish

Full Access Member

- Joined

- Nov 6, 2021

- Posts

- 3,111

- Reaction score

- 16,587

- Location

- Prairieville, LA

- First Name

- Andrew

- Truck Year

- 1987

- Truck Model

- V1500

- Engine Size

- 350/5.7

When you have tightened it too much the steering wheel will no longer return to center on its own. You will have to turn the wheel back to center every time while a properly adjusted steering box will allow the steering wheel to come back to center/straight as soon as you are moving.

75gmck25

Full Access Member

- Joined

- Oct 13, 2016

- Posts

- 2,493

- Reaction score

- 2,565

- Location

- Northern Virginia

- First Name

- Bruce

- Truck Year

- 1975

- Truck Model

- K25 Camper Special TH350 NP203

- Engine Size

- 5.7

With an old steering box it can be difficult to take out all the play and at the same time keep it loose enough to prevent binding.. Simplest process is to tighten it a 1/4 turn (or less) each time and then drive the truck and check it to make sure it returns to center on its own.

TotalyHucked

Full Access Member

- Joined

- Feb 24, 2020

- Posts

- 5,012

- Reaction score

- 16,715

- Location

- Auburn, Georgia

- First Name

- Zach

- Truck Year

- 1985

- Truck Model

- Sierra 1500

- Engine Size

- 5.3

I've always been taught you don't touch that. That's for setting up the box preload when new, not for tightening up a worn out box. My dad and a few of his friends worked on these when they were new/just a few years old and they all preach the same thing. If your box has slop in it, rebuild or replace. Do not "tighten" the box. It can bind on you at any time if you get it wrong, it's not worth the risk.

nvrenuf

Full Access Member

- Joined

- Jul 30, 2010

- Posts

- 2,201

- Reaction score

- 3,059

- Location

- Mobile, Al.

- First Name

- John

- Truck Year

- 1991

- Truck Model

- K5

- Engine Size

- 454

I've never read about anyone making adjustments that helped long term. Most stories of adjustment say it got tighter short term, then the box takes a turn for the worse and needs to be replaced presumably from being overtightened and killing itself from the inside out.

Steppin Razor

Full Access Member

- Joined

- Apr 21, 2023

- Posts

- 61

- Reaction score

- 41

- Location

- Houston

- First Name

- S

- Truck Year

- 1977

- Truck Model

- C10 silverado

- Engine Size

- 350

That adjustment moves the pitman arm up and down. To get rid of slack, there is a spanner nut on the gearbox where the input shaft is. Loosen that and adjust it there.

75gmck25

Full Access Member

- Joined

- Oct 13, 2016

- Posts

- 2,493

- Reaction score

- 2,565

- Location

- Northern Virginia

- First Name

- Bruce

- Truck Year

- 1975

- Truck Model

- K25 Camper Special TH350 NP203

- Engine Size

- 5.7

The GM manual says to adjust the gearbox slack first and then the small free play adjuster on top. The catch is that the gearbox is adjusted before you mount it in the truck, and the free play is adjusted with the tie rods disconnected, using a spring scale to measure the tightness.

Bottom line - very few folks take time to do it properly, so the compromise is to tighten it up about a 1/4 turn at a time and see how it works.

Bottom line - very few folks take time to do it properly, so the compromise is to tighten it up about a 1/4 turn at a time and see how it works.

rusted nuts

Full Access Member

- Joined

- Mar 5, 2023

- Posts

- 809

- Reaction score

- 1,422

- Location

- Pa.

- First Name

- Jeffrey

- Truck Year

- 1979

- Truck Model

- k20

- Engine Size

- 4cly diesel

A 20 year old use steering gearbox Can not be adj. very well cause most of the wear is on the teeth that are used going down a straight road with little wear when turning left or right. what I'm trying to say is most all the wear is only on a small part of the gear.

Last edited:

Ricko1966

Full Access Member

- Joined

- Apr 11, 2017

- Posts

- 6,965

- Reaction score

- 11,989

- Location

- kansas

- First Name

- Rick

- Truck Year

- 1975

- Truck Model

- c20

- Engine Size

- 350

Stepping Razor was right,but not complete.That adjustment moves the pitman arm up and down. To get rid of slack, there is a spanner nut on the gearbox where the input shaft is. Loosen that and adjust it there.

You are supposed to adjust both, just like doing a diff,you adjust the big nut on the end first for proper end clearance then adjust the Allen for depth. But you aren't supposed to adjust them after there is wear that's for setting them up on rebuild. If it's sloppy something is worn,not out of adjustment and as others have said it will damage the box further,probably to the point of not being rebuildable. There is probably an egg shaped bushing adjusting it will put pressure and will wear through the bushing then your wear will be on the shaft and the housing.

squaredeal91

Full Access Member

- Joined

- Mar 10, 2023

- Posts

- 2,759

- Reaction score

- 5,112

- Location

- Cave junction Oregon

- First Name

- Greg bush

- Truck Year

- 1991 SB

- Truck Model

- K30

- Engine Size

- 5.9 Cummins 12 valve

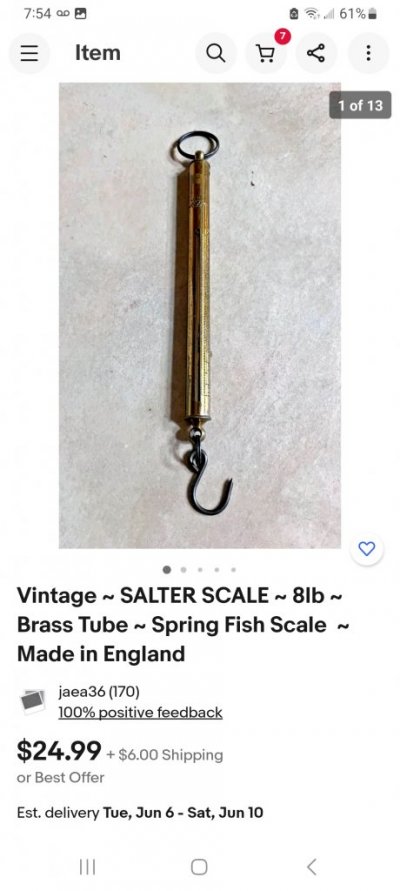

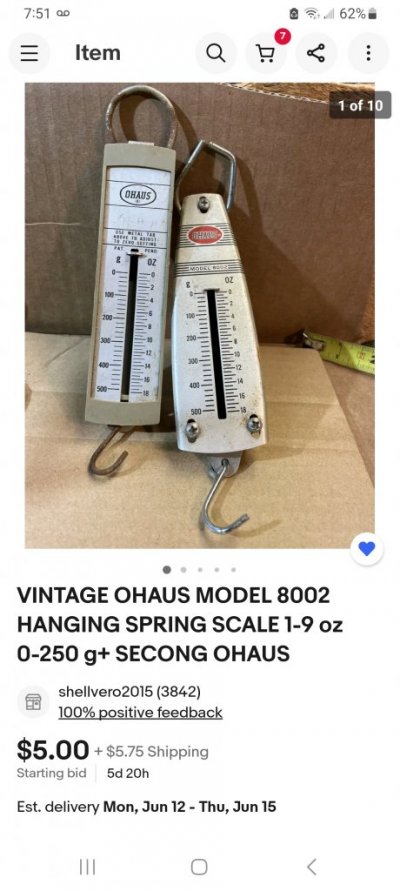

@75gmck25 ) Spring scale like these? For example. Depending upon what weight was spec.

Attachments

Ricko1966

Full Access Member

- Joined

- Apr 11, 2017

- Posts

- 6,965

- Reaction score

- 11,989

- Location

- kansas

- First Name

- Rick

- Truck Year

- 1975

- Truck Model

- c20

- Engine Size

- 350

You can use a fishing scale but you're not suppose to adjust a worn box.@75gmck25 ) Spring scale like these? For example. Depending upon what weight was spec.

75gmck25

Full Access Member

- Joined

- Oct 13, 2016

- Posts

- 2,493

- Reaction score

- 2,565

- Location

- Northern Virginia

- First Name

- Bruce

- Truck Year

- 1975

- Truck Model

- K25 Camper Special TH350 NP203

- Engine Size

- 5.7

That is the type of spring scale you use, and from what I recall you use it to measure the turning resistance of the box arm.

75gmck25

Full Access Member

- Joined

- Oct 13, 2016

- Posts

- 2,493

- Reaction score

- 2,565

- Location

- Northern Virginia

- First Name

- Bruce

- Truck Year

- 1975

- Truck Model

- K25 Camper Special TH350 NP203

- Engine Size

- 5.7

On a related topic, has anyone found a reliable new replacement brand steering box? I’ve seen complaints here about a new Borgesen box loosening up and being just as bad as the original box. I would be willing to consider a brand new box if it would properly tighten up my steering.

From looking at box rebuild kits online, they seem to be mostly seals and other small parts, so I don’t see how they do much more than seal any leaks. If the wear is on the internal teeth and you don’t replace them, I don’t see how a rebuild will help tighten up the steering.

From looking at box rebuild kits online, they seem to be mostly seals and other small parts, so I don’t see how they do much more than seal any leaks. If the wear is on the internal teeth and you don’t replace them, I don’t see how a rebuild will help tighten up the steering.

Rusty Nail

Full Access Member

- Joined

- Jan 29, 2015

- Posts

- 10,103

- Reaction score

- 10,255

- Location

- the other side of the internet

- First Name

- Rusty

- Truck Year

- 1977

- Truck Model

- C20

- Engine Size

- 350sbc

Dude I have been very happy with the LARES brand box I put in the 88 Blazer because it is Tha Shizznit.

Factory steering ratio is 7.8/1

A (1988) Z-28 box is 12.5/1

A LARES box is 16/1 and it bolts on.

Bout twice the price of a parts store rebuilt = Choose wisely.

www.larescorp.com

www.larescorp.com

Hope this helps!

Factory steering ratio is 7.8/1

A (1988) Z-28 box is 12.5/1

A LARES box is 16/1 and it bolts on.

Bout twice the price of a parts store rebuilt = Choose wisely.

Home - Lares Corporation

Hope this helps!

Attachments

Last edited:

Rusty Nail

Full Access Member

- Joined

- Jan 29, 2015

- Posts

- 10,103

- Reaction score

- 10,255

- Location

- the other side of the internet

- First Name

- Rusty

- Truck Year

- 1977

- Truck Model

- C20

- Engine Size

- 350sbc

xc_hide_links_from_guests_guests_error_hide_media

Similar threads

- Replies

- 5

- Views

- 1K

- Replies

- 56

- Views

- 4K