GreaseDog

Full Access Member

- Joined

- Aug 8, 2010

- Posts

- 1,189

- Reaction score

- 33

- Location

- Elkhart, IN

- First Name

- Jeremy

- Truck Year

- 1977 K20

- Truck Model

- 1980 K2500

- Engine Size

- 350

i've had several guys ask me about swapping a hydro clutch into an automatic truck, or a truck with a factory mechanical clutch. so i thought that this post could be useful in the future.

for starters, you need the proper 85-87 hydraulic belhousing. the hydraulic belhousing from an IFS truck may work, but the slave cylinder is on the wrong side. you'll also need the specific hydraulic clutch pedal assembly, and the support rods that go between the pedal pivot and the firewall. everything else is available, as they're wear parts. some parts may be tougher to find, but they are available. i've heard of guys having problems finding a hydraulic line to go between the master and the slave. IIRC they are available from Napa.

the studs on the end of the supports are used to mount the master cylinder. proper positioning of these support rods, and the master cylinder are critical to proper geometry and operation of the clutch. fortunately the wiper motors are positioned the same on all trucks in the same position away from the brake pedal, so you can use the bolts for the wiper motor as a refrence point to accurately drill the proper holes.

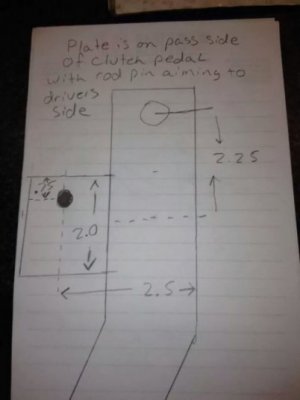

here are the measurements to locate the master cylinder and the support rods.

on trucks 84 and newer, you will often find dimples in the firewall where the center of these holes will be, if you find them, you can just use them and drill the holes to the proper size and be done with it.

the measurements are courtesy of TJ (aka big83chevy4x4)

See Post #22 for further template info: http://www.gmsquarebody.com/forum/showpost.php?p=230533&postcount=22

for starters, you need the proper 85-87 hydraulic belhousing. the hydraulic belhousing from an IFS truck may work, but the slave cylinder is on the wrong side. you'll also need the specific hydraulic clutch pedal assembly, and the support rods that go between the pedal pivot and the firewall. everything else is available, as they're wear parts. some parts may be tougher to find, but they are available. i've heard of guys having problems finding a hydraulic line to go between the master and the slave. IIRC they are available from Napa.

the studs on the end of the supports are used to mount the master cylinder. proper positioning of these support rods, and the master cylinder are critical to proper geometry and operation of the clutch. fortunately the wiper motors are positioned the same on all trucks in the same position away from the brake pedal, so you can use the bolts for the wiper motor as a refrence point to accurately drill the proper holes.

here are the measurements to locate the master cylinder and the support rods.

You must be registered for see images attach

on trucks 84 and newer, you will often find dimples in the firewall where the center of these holes will be, if you find them, you can just use them and drill the holes to the proper size and be done with it.

the measurements are courtesy of TJ (aka big83chevy4x4)

See Post #22 for further template info: http://www.gmsquarebody.com/forum/showpost.php?p=230533&postcount=22