dec322

Junior Member

- Joined

- Feb 10, 2024

- Posts

- 22

- Reaction score

- 19

- Location

- Indiana

- First Name

- David

- Truck Year

- 1984

- Truck Model

- Scottsdale K10

- Engine Size

- 305

Hi all! I have an 84 scottsdale with a stock 305. I have been fighting with a squeal that is most pronounced during acceleration. I bought this from a buddy in a different state and have owned it about a year. The squeal would come and go but now it's here to stay. Here is what has been done:

1. New belts before I bought it. I'd guess the truck has around 5k on the belts

2. Checked tightness of belts. I can twist them 90 degrees but cannot pull them on any of the pulleys

3. The battery gauge in the truck moves when it starts to squeal but I didn't notice much of a different on the multi-meter (probably need to test again)

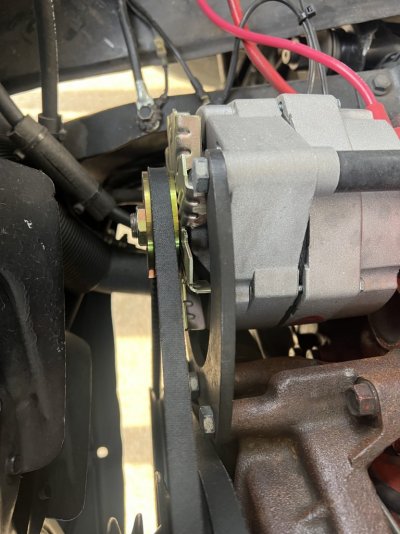

4. It sounds like it is coming from the alternator. The one in the truck is 66 amp from 2002 so I replaced it. I bought a 78 amp rebuilt unit from Autozone (running a new head unit, 2 channel amp, 6x9s and powered sub....installed last week). The fan on the unit looked like it wobbled when you spin it. It was tight but the fan had a wave about it. I installed it to see and the squeal was the same. The alternator pulley/fan was hot and the belt was hot (only ran 45 seconds).

5. Today I replaced the new one (installed yesterday) with the 94 amp unit from O'riellys hoping that the fan was bent and that was the cause of the squeal. The sound is the same. The pulley gets hot and the belt gets warm.

Is it possible it's the alternator and I got two bad ones? I wouldn't think it should be getting hot...especially after running only 45 seconds.

I'm about to start eliminating belts (within reason) to see if I can narrow it down.

1. New belts before I bought it. I'd guess the truck has around 5k on the belts

2. Checked tightness of belts. I can twist them 90 degrees but cannot pull them on any of the pulleys

3. The battery gauge in the truck moves when it starts to squeal but I didn't notice much of a different on the multi-meter (probably need to test again)

4. It sounds like it is coming from the alternator. The one in the truck is 66 amp from 2002 so I replaced it. I bought a 78 amp rebuilt unit from Autozone (running a new head unit, 2 channel amp, 6x9s and powered sub....installed last week). The fan on the unit looked like it wobbled when you spin it. It was tight but the fan had a wave about it. I installed it to see and the squeal was the same. The alternator pulley/fan was hot and the belt was hot (only ran 45 seconds).

5. Today I replaced the new one (installed yesterday) with the 94 amp unit from O'riellys hoping that the fan was bent and that was the cause of the squeal. The sound is the same. The pulley gets hot and the belt gets warm.

Is it possible it's the alternator and I got two bad ones? I wouldn't think it should be getting hot...especially after running only 45 seconds.

I'm about to start eliminating belts (within reason) to see if I can narrow it down.