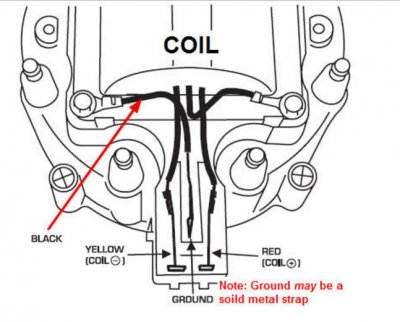

Looks like the coil is good if I'm using this meter correctly..how do I check for 10 volts at the b+ ?? Like what do I set this meter at??

You must be registered for see images attach

I don't no what this stuff means ..dcv?acv?dca?

dcv = direct current voltage (as found in automotive applications)

acv = alternating current voltage (as in household electrical systems)

dca = direct current amperage

Current is simply the term used to describe the movement of electrons within a

conductor (a conductor is a wire - for this discussion). And, when there are a series of conductors and devices that are connected together to form one continuous, unbroken loop - that is called a

circuit.

If the electrons flowing in a conductor are continuously moving in just one direction - that's called

direct current. And as above, if the conductors form a continuous loop - with the electrons flowing around and around in the same direction - that is called a

direct current circuit.

In an

alternating current circuit, everything's the same as described above for a DC circuit - with one major difference. The electrons flow first in one direction for a certain distance. Then they stop, turn around and begin flowing backwards through the conductor - opposite their original direction. They keep moving backwards until they get to their original starting point. Then they stop, turn around and begin flowing in their original direction.

Being an electron in an AC circuit kind of sucks. They move just as far and do just as much work as the electrons in a DC circuit - but they never get anywhere.

Think of voltage as the water pressure in a garden hose with a hand operated spray nozzle at the end. Even when the nozzle is turned off, there's still pressure in the garden hose.

Even when a light is switched off there's still voltage in the energized portion of the circuit.

Think of current as the flow rate of water in the garden hose - like how many gallons per minute are moving through it. When the nozzle is turned off, there's still pressurized water in the hose, but there's no flow.

When a light is turned off the electrons are still in the wire, but they aren't flowing anywhere -- there's zero current.

The hei was properly assembled I did it a few months ago and it has been a daily driver since. One cold below 0 morning I went out to start it with no luck sprayed some either in it and somehow blew a fuse ne'er the starter and had nothing at the key. Replaced that now I lack spark.

I'd like to hear more about that. I can't imagine how shooting a blast of ether down the carburetor throat could possibly cause a fusible link (located way down by the starter) to fry. Did you have a fire?

But looks as if I have power at the distributer while testing with s light tester is it enough?

It probably is - but you should use your new meter as described above to verify the required 10 volts.

I probably shouldn't say this but, I'm gonna anyway. Money spent to buy good quality tools, is always money well spent. That meter is pretty weak, it lacks even the most basic features. No auto ranging - or an audible continuity setting. I see them at HF for like $5. I mean you don't have to buy Snap-On tools but don't get the cheapest possible tool available. Stuff like that fails so quickly, you'll end up spending more in the long run.