Scary Fast atx

Member

- Joined

- Sep 30, 2021

- Posts

- 33

- Reaction score

- 12

- Location

- Austin Texas

- First Name

- Javier

- Truck Year

- 1981

- Truck Model

- C10

- Engine Size

- 305

Been reading a lot of other threads about these factory oil gauges and had some questions for you electrical gurus

My original sender was leaking, so I replaced it with a 60psi unit from Rock Auto

I replaced it, but gauge does not respond to the engine rev'ing, stays low at like 10-15psi

Tested the new sender with my radiator pressure tester to 15-30 psi and it was reading much higher than I was expecting, like 40-60ohms

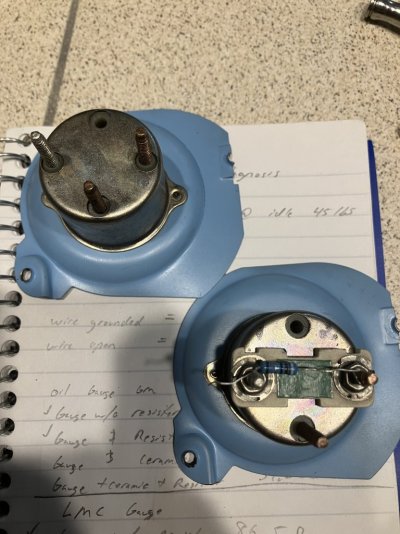

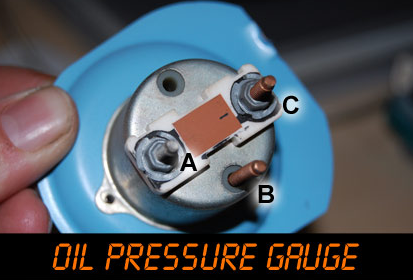

I also pulled out the gauge and tested the ceramic resistor and it is open (its a pink resistor, but dont know what resistance that equates to, my googlefu couldnt pull up anything)

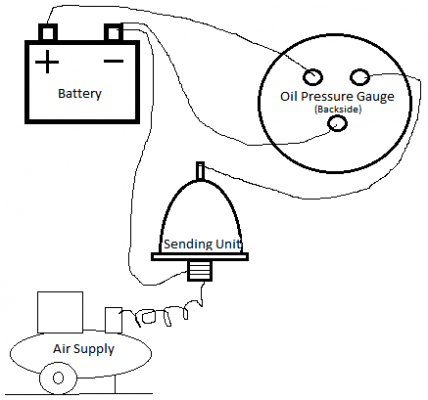

I ordered a 90ohm resistor and put it on the back and am trying to test it on the bench but its staying over 60psi, I was testing with an old fuel level sender that had some dead spots, so not exactly "precision instruments"

Can anybody help me out with the resistance on the oil pressure gauge (pink color)?

also has anyone seen a higher than expected oil pressure sender resistance?

(its this one https://www.rockauto.com/en/moreinfo.php?pk=939037&cc=1030723&pt=4588&jsn=18)

Thanks!

My original sender was leaking, so I replaced it with a 60psi unit from Rock Auto

I replaced it, but gauge does not respond to the engine rev'ing, stays low at like 10-15psi

Tested the new sender with my radiator pressure tester to 15-30 psi and it was reading much higher than I was expecting, like 40-60ohms

I also pulled out the gauge and tested the ceramic resistor and it is open (its a pink resistor, but dont know what resistance that equates to, my googlefu couldnt pull up anything)

I ordered a 90ohm resistor and put it on the back and am trying to test it on the bench but its staying over 60psi, I was testing with an old fuel level sender that had some dead spots, so not exactly "precision instruments"

Can anybody help me out with the resistance on the oil pressure gauge (pink color)?

also has anyone seen a higher than expected oil pressure sender resistance?

(its this one https://www.rockauto.com/en/moreinfo.php?pk=939037&cc=1030723&pt=4588&jsn=18)

Thanks!