The wiper motor has three brushes; the "common" the low speed, and the high speed. When the ignition switch is "ON," power is applied to the common brush. The low speed and high speed brushes are connected to their respective ground via the control switch. When the control switch is positioned at "HI" or "LO" speed, a ground path is connected to the high or low speed brush in the motor. The motor runs at the switch selected speed.

I would suspect that (if the motor is original) it is just that your brushes have worn out and are barely making contact. When the wiper blades are in the mid-swipe part of their sweep arc they are putting the greatest load on the motor.

Most folks don't feel like breaking open the wiper motor casing, sourcing new brushes, soldering the pigtails in and then re-assembling everything. Not when a reman motor is less than $50 and a JY unit is about $15.

I would check/change the motor before tearing into the linkage. The motor can be changed without pulling the cowling, arms, etc.

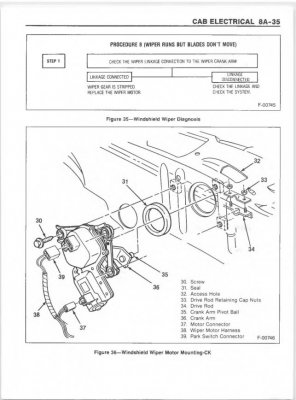

Just release the three mounting screws, and gently pull the motor away from the firewall. There is sufficient flex in the wiper linkage to do this. You will see a crankarm with a ball on it that connects to the linkage - leave that (ball joint) connection alone.

The other end of the arm is secured to the motor shaft with a nut. That nut can be released (and the crank pulled off the shaft) by inserting a wrench between the firewall and the wiper motor frame and onto the nut. That is how I disco the arm from the shaft.

But the textbook way is to use the hole provided to release the nut. It is offset quite a bit from the connection. That makes it hard enough. But also, more often than not, I drop the nut down into the depths of the plenum and have to spend a couple of hours fishing it out.

When you go to reassemble the crank on the motor shaft be SURE that they are indexed to each other correctly. By that I mean, it is important that both the motor and wiper arms are in the fully parked position.

The crank arm can go on the shaft in 2 different positions. If the arm is 180 degrees off from the normal angle, it will suck.

The first time you operate the wipers, the blades/wiper arms will work beautifully - except for the fact that they will park at the top of the windshield. You will have to do the job again.

The wiper arms are easy - just push them down to a point where the blades are almost touching the windshield gasket.

To preset the motor to park position, just plug in the wiring harness connections, turn the switch on and run it for a couple of revolutions. Turn the wiper motor off at the switch and then mate the motor shaft to the crank arm.

It might sound wicked involved, but everything will become obvious as you do the replacement. Here are a couple of pictures to help explain - I can't type any more: