Doppleganger

Full Access Member

- Joined

- May 24, 2019

- Posts

- 11,782

- Reaction score

- 54,478

- Location

- OH-MI: Just like it sounds

- First Name

- Chris

- Truck Year

- 1985

- Truck Model

- K20

- Engine Size

- 5.7

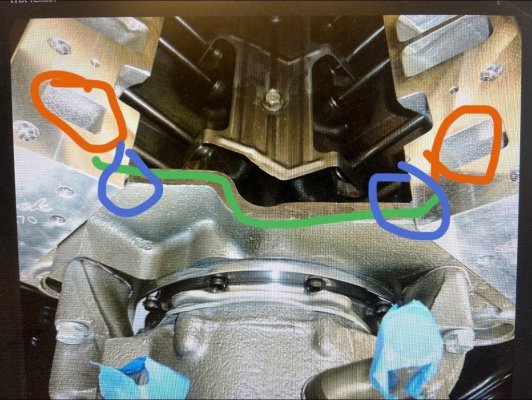

On this ProFlo4 FI setup, they mention using a gasket maker on the front and back edge of where the FI setup (intake) sits. Actual gaskets everywhere else.

I can take a good guess on which Permatex to use, but just tossing this out there if anyone else has already BTDT. Not all gasket makers are alike.

THX

I can take a good guess on which Permatex to use, but just tossing this out there if anyone else has already BTDT. Not all gasket makers are alike.

THX