- Joined

- Aug 29, 2010

- Posts

- 47,014

- Reaction score

- 9,015

- Location

- OKC, OK

- First Name

- HotRod

- Truck Year

- 85 K20 LWB

- Truck Model

- Silverado

- Engine Size

- 454 - Turbo 400 - 3.73

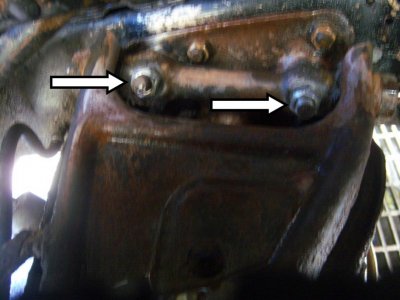

Anyone have any ideas or suggestions how I can get these nuts off of these studs? The pic is terrible but you'll get the idea. As you can tell, my caster and camber shims have fallen out. I can't get the truck aligned because the knurled studs just spin when I put a wrench on the nuts, so I can't loosen the nuts. This is actually quite dangerous to be driving. The wheel is leaning in at the top about 2 inches and whole wheel when jacked up, I can move the wheel and entire upper A arm assembly in about a 3 inch circle. So everytime I hit a bump or railroad track, the stud is getting hammered on, and I'm afraid going to break and fold the tire under the truck while driving. Seems the only place I can get these studs is LMC. Even then, I wonder if the studs will hold in place. It may not be the studs knurling that is bad, but maybe the frame hole is oversized. Has anyone else ever encountered this?