- Joined

- Aug 29, 2010

- Posts

- 47,014

- Reaction score

- 9,014

- Location

- OKC, OK

- First Name

- HotRod

- Truck Year

- 85 K20 LWB

- Truck Model

- Silverado

- Engine Size

- 454 - Turbo 400 - 3.73

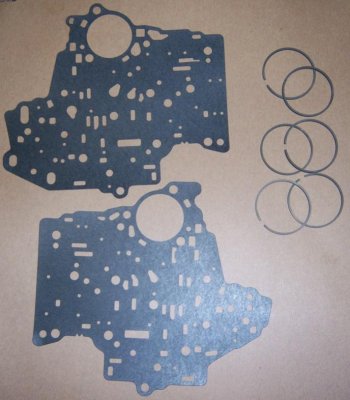

The other updgade, which is a very rare hard to find part. Is the reaction carrier drum for wedge or dog bone element type one way clutch similar to a sprag. Realistically, it is not a necessary upgrade in a Turbo 400. This is what is used for 1st and Reverse. When does something like this come in handy or when you might want to prefer the use of it??? If you are running a drag car, and you launch hard off the line, or if you are using a trans brake in a high performance application. Being that in most cases, and even if towing some weight, you are not leaving very hard in first gear, the roller type is quite strong and effective, just that the wedge element type is even better. Here is a pic I robbed of the differant styles side by side. Again the differance is easy to see. This part is rare and hard to find because it was only used on early Turbo 400's. The first year of THM400 was 1964 and this carried thru only to 1966 for sure and some 1967 models had it. How many 64-67 THM400's do you think are still around??? I do happen to have one that is still OEM and never been cracked open. Its a gold mine transmission. I haven't had the need yet to use it, but will someday. Its also a variable pitch aka switch pitch torque converter trans. It has a solenoid in it to change the stall of the torque converter. It has the standard 1400-1600 stall, then by hitting a switch, the vanes in the TC will adjust and the stall is now 1800-2200. There are also aftermarket converters or you can have one built to your own specs. So lets say you want 1800 stall and then flip the switch and you can now have 2500 stall. NICE idea. Perfect for making a sleeper and that is exactly what I intend to use that trans for someday. Here is the pic of the differant reaction carriers. One on the Left is after 67 for sure, and the better on the right is early 67 on back to 64. Something else you find really fascinating, but I find quite scrary, is where you can find this wedge style low/reverse clutch. You call a GM dealership, chances are they don't have it in stock but can order it and its expensive. BUT, you can go right down to your local FORD, yes, I said FORD stealership and they will likely have it in stock, and because its more common there, it will not cost an arm and a leg compared to the GM stealership. The part is used in 4R100 and most likely E4OD FORD 4 speed overdrive transmissions which are very common models these days. Keep in mind, I am just reffering to the dog bone wedge clutch, not the drum itself. So if you have drum already, go the FORD dealership and get the clutch. You're now set up strong enough for mega hp and a hard launch off of a trans brake. Mind Blowing isn't it???

Attachments

Last edited: