Ricko1966

Full Access Member

- Joined

- Apr 11, 2017

- Posts

- 4,067

- Reaction score

- 5,918

- Location

- kansas

- First Name

- Rick

- Truck Year

- 1975

- Truck Model

- c20

- Engine Size

- 350

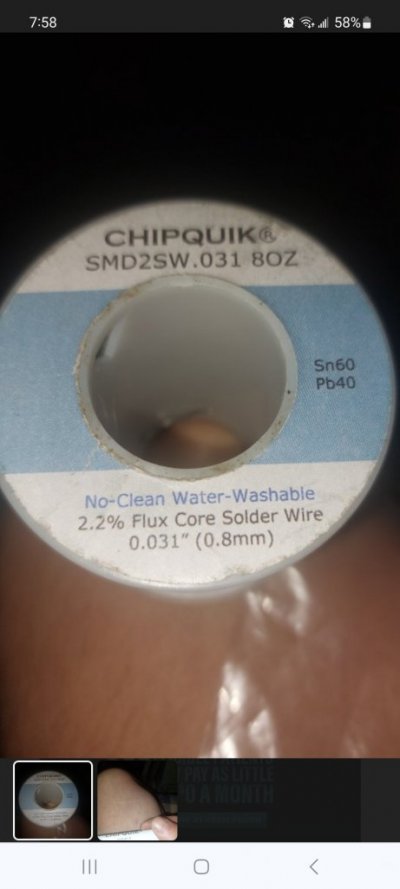

Okay I've been modding cordless tools and batteries for a while now. So just sharing a little of what I've learned. A simple way to run 9.6 and 12v tools is gut the tool battery and graft in a chord for a cigarette lighter plug,then you can run the tool off of a jumper box,the cigarette lighter or charger clips with a lighter socket for under the hood,in front off the car,on the boat whatever. Same mod for 18v but pick up the green battery cap pictured for running power wheelers on Ryobi batteries it's like 10 bucks on ebay. Most of the batteries I've done, the easy way is to clip the end battery with tool connector out of the battery pack. Solder on leads at the connector then hot glue it with the one battery into the stalk. I've use different types of connectors,and plugs,I've used different kinds of tool batteries. Cigarette lighter plugs and Ryobi batteries seem the best,I don't want to list all the different reasons. Number 1 reason for using Ryobi batteries is they are designed to fit directly into their nicad tools. They didn't design a new battery and a tool,just a battery that self contained,monitored voltage,amperage etc. Here's some pics a free Craftsman impact and battery ,I modded for 18v Corded use. I am eventually going to hard mount the green plastic socket and lighter socket into the lid of a tool box,I don't like the way wires bend at the top and am afraid they will eventually break in the jacket.Plus the tool box will give me a place to store batteries and a charger. Also I've learned how to bring totally dead Ryobi batteries back from the dead,I bought 10 new DOA batteries on ebay for $36.00. The learning process with this has taught me a lot, run your wires out the bottom of the tool battery,not the back,Ryobi batteries work best,use crimp on bullet disconnect inside the tool. The inspiration for this was buying,Milwaukee, DeWalt,Ryobi,Rigid,Kobalt batteries wasn't cost effective and I bought all these tools over time not thinking about not being compatible batteries.

Attachments

Last edited: