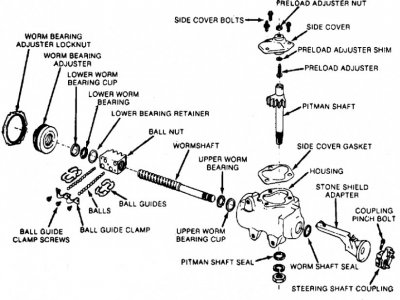

Disassemble 800 -808

For these steps, refer to the 3 images at the bottom of the post. They are figures 5,6 & 7 from top down:

1.Referring to Fig. 3, position gear in vise with gear housing end plug facing up.

2.Rotate gear housing end plug retaining ring so that one end of ring is over hole in housing. Spring one end of ring with a punch to allow screwdriver to be inserted to lift ring out, Fig. 5.

3.Rotate coupling flange counterclockwise until rack-piston just forces end plug out of housing. Remove plug from housing. Do not rotate any further than necessary or balls fall out of their circuit and pitman shaft teeth and rack-piston will become disengaged.

4.Remove rack-piston end plug, using a 1/2 inch square drive. To make removal easier, tap rack-piston end plug with a plastic mallet to unseat threads. This is important as end plug is tightened to 75---80 ft-lbs during assembly and could break during removal if not handled carefully.

5.Remove lock nut from pitman shaft adjuster screw and discard.

6.Remove four side cover retaining screws and washers from cover.

7.Rotate pitman shaft adjuster screw with an Allen wrench until side cover is lifted free of housing.

8.Separate side cover from pitman shaft; discard side cover O-ring seal.

9.Turn coupling flange until pitman shaft teeth are centered in housing.

10.Tap end of pitman shaft with a soft mallet and slide pitman shaft out of housing.

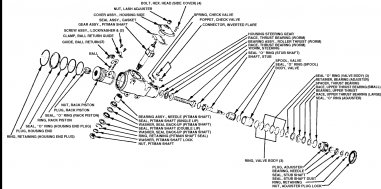

11.Remove housing end plug O-ring seal and discard.

12.Insert Rack-Piston Arbor into rack-piston against end of worm, Fig. 6. Turn coupling flange counterclockwise, while holding tool tightly against worm, to force rack-piston onto arbor, and remove rack-piston from gear housing.

13.Remove stub shaft-to-coupling flange retaining screw and remove flange.

14.Remove adjuster plug lock nut by breaking it loose with hammer and punch, and remove lock nut from housing.

15.Loosen adjuster plug and remove from housing, Fig. 7.

16.Remove valve assembly by grasping stub shaft and pulling out.

17.Remove worm, lower thrust bearing and races from upper end of housing.

Disassemble Housing

1.Remove pitman, shaft outer dust seal retaining ring.

2.Remove outer dust seal.

3.Remove seal (double lip) by inserting offset screwdriver between seal and back-up washer and prying out of housing.

4.Remove back-up washer.

5.Remove seal (single lip) by cutting and collapsing seal.

6.Remove pitman shaft needle bearings (if necessary) with a suitable driver.

7.If connectors are to be removed, tap threads in holes of connectors using 5/16-18 NF tap. Remove connectors by using threaded bolt into tapped holes with washer and nut as extractor.

You must be registered for see images attach

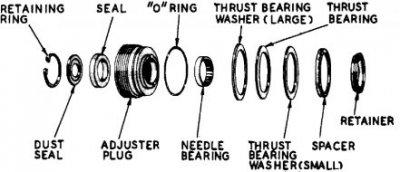

Replacing Valve Spool Dampener O-Ring - refer to image above:

The rotary valve assembly includes the valve body, valve spool and stub shaft assembly. All these parts are precision units and are hydraulically balanced at the factory. Under no circumstances are parts in this unit to be replaced or interchanged with other parts or units. If unit parts are scored or damaged the entire rotary valve assembly is to be replaced. The O-ring should be replaced only if the gear squawks.

1.To replace the valve spool dampener O-ring, work spool spring into bearing diameter of stub shaft and remove spool spring.

2.Tap end of stub shaft gently against workbench to remove valve spool. The diametrical clearance between the valve body and spool may be as low as .0004 inch. The slightest cocking of the spool may jam it in the valve body.

3.Remove valve spool dampener O-ring.

4.Install new O-ring in valve spool groove, then lubricate seal in automatic transmission fluid. Do not allow seal to twist in groove.

5.With notch end of spool towards valve body, install spool, aligning spool notch with pin in stub shaft, Fig. 8.

6.Because of the small clearance between spool and valve body, extreme care must be taken when assembling these parts. Push spool evenly and slowly with a slight oscillating motion until spool reaches drive pin. Before pushing spool completely in, make sure dampener O-ring seal is evenly distributed in spool groove. Slowly push spool completely in, with extreme care taken not to cut or pinch O-ring seal.

7.Slide spool spring over stub shaft and work spring into position.

,

,