RaysnCayne

Junior Member

- Joined

- Dec 6, 2020

- Posts

- 15

- Reaction score

- 6

- Location

- Richmond

- First Name

- Zach

- Truck Year

- 1987

- Truck Model

- R10 Custom Deluxe

- Engine Size

- 305

Hey guys,

I feel like I see a lot of talk and info about pinion angles for lifted rigs, but precious little for lowered ones.

My SWB '87 R10 (currently undergoing a mild "hot rodding" makeover with a freshly-installed 3.5"/4.5" drop) is up on stands with full weight on it. I'd like to see if I can dial in a decent pinion angle before taking it off the stands and hitting the road.

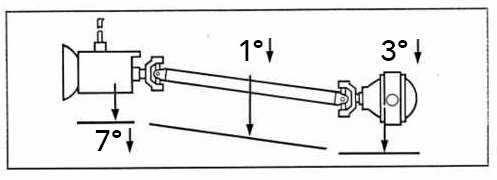

I'm currently looking 6.8º down on the trans tailshaft face and 7º up on the differential yoke. That's pretty darn close to parallel. But this is my first rodeo lowering a C10 and working with pinion angles on a leaf spring vehicle. This will be a very tame cruiser (still has the OG 305). So I wasn't anticipating a whole lot of "spring wrap" and thus not planning on the differential angle to change much. But a friend said I should try to bring the rear angle down about 2º (shoot for ~5º up instead of 7º) because even light cruising will cause the axle to wrap.

I've also been told by a guy that does a lot of 4/6 drops that he's never touched the pinion angle and his C10s ride great.

I'd love to hear some insight from those more experienced in this area. Am I good as-is, or should I do some shimming to the rear angle? Or am I way off on all accounts?

I feel like I see a lot of talk and info about pinion angles for lifted rigs, but precious little for lowered ones.

My SWB '87 R10 (currently undergoing a mild "hot rodding" makeover with a freshly-installed 3.5"/4.5" drop) is up on stands with full weight on it. I'd like to see if I can dial in a decent pinion angle before taking it off the stands and hitting the road.

I'm currently looking 6.8º down on the trans tailshaft face and 7º up on the differential yoke. That's pretty darn close to parallel. But this is my first rodeo lowering a C10 and working with pinion angles on a leaf spring vehicle. This will be a very tame cruiser (still has the OG 305). So I wasn't anticipating a whole lot of "spring wrap" and thus not planning on the differential angle to change much. But a friend said I should try to bring the rear angle down about 2º (shoot for ~5º up instead of 7º) because even light cruising will cause the axle to wrap.

I've also been told by a guy that does a lot of 4/6 drops that he's never touched the pinion angle and his C10s ride great.

I'd love to hear some insight from those more experienced in this area. Am I good as-is, or should I do some shimming to the rear angle? Or am I way off on all accounts?