Spookee

Junior Member

- Joined

- Nov 4, 2023

- Posts

- 25

- Reaction score

- 37

- Location

- oregon

- First Name

- hannah and pat

- Truck Year

- 1984

- Truck Model

- k10

- Engine Size

- 350

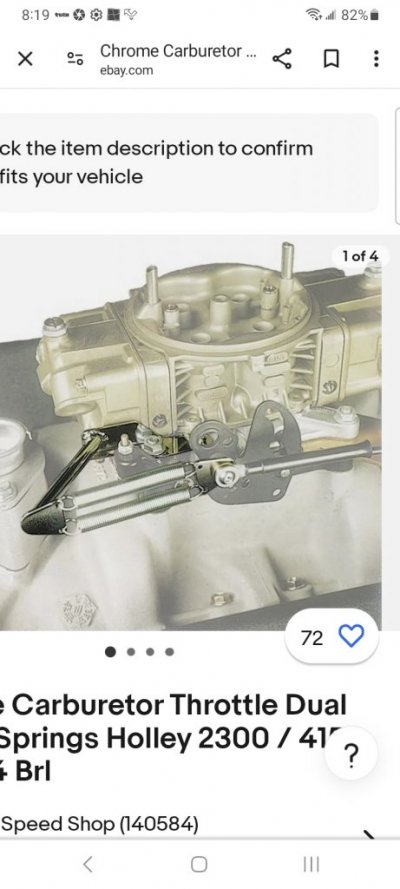

Hi! We previously had issues with our transmission and got it rebuilt a few months ago. So we are pretty nervous about messing it up! Does it matter where this spring connects? The carb was cleaned over the weekend and when we picked it up the spring was connected at the bottom of the metal piece, but before it had been connected in the loop. We are so new to classic trucks and I really don’t know much beyond what I can find on YouTube or the shop manual so I’m hoping wiser minds can give me some input. Thanks