78bigblock

Member

- Joined

- Dec 8, 2013

- Posts

- 37

- Reaction score

- 0

- Location

- North Carolina

- First Name

- Adam

- Truck Year

- 1978

- Truck Model

- Silverado

- Engine Size

- 454

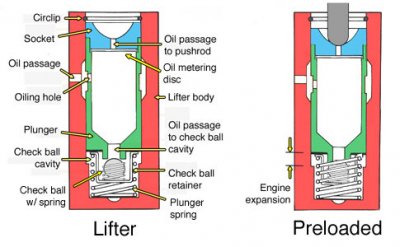

Open to any ideas. I had my #4 intake pushrod catastrophically fail. The upper ball end is completely gone. About 535 miles since rebuild. Comp cams magnum pushrod, comp cams 1.72:1 roller tip rocker. Set to zero lash then 1/2 turn. Looks like maybe it wasn't rotating properly and just chewed itself up. Replacements on order. Was this possibly due to setting it up too loose during break in? 1/4 turn... Or bad lifter? I'm at a loss. After cam break in I torqued everything down to 1/2. This is the only one I'm having issues with. I am however mulling the idea of yanking the motor and checking all of the bearings and cleaning out all of the metal particles. As minimal as it is.

You must be registered for see images attach

You must be registered for see images attach