LAsquarebody

Junior Member

- Joined

- Oct 19, 2021

- Posts

- 14

- Reaction score

- 6

- Location

- Los Angeles

- First Name

- Saxon

- Truck Year

- 1984

- Truck Model

- GMC K1500

- Engine Size

- crate 350

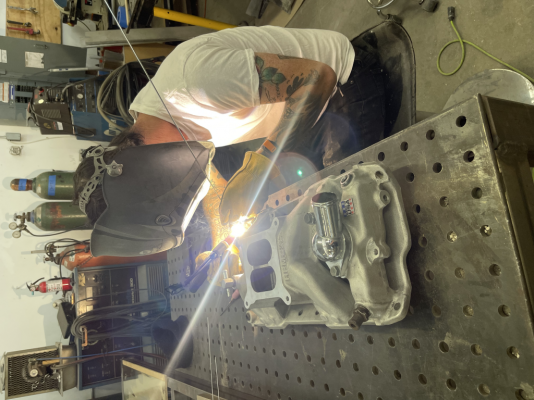

Hey guys, well its time to charge the heart beat in this old Squarebody. I have done a lot of work on cars and trucks over the years but its been a long time since I did a full swap. I was curious if anyone had a how to video that could walk me back thru the little things I might have forgotten about prepping a vehicle for an engine pull and reload? Ive googled a bit but keep getting things that havent been as helpful as I'd like.

Anyways Im planning to start on this next weekend.

Pics to follow

Thanks for your help

Anyways Im planning to start on this next weekend.

Pics to follow

Thanks for your help