InVision

Member

- Joined

- Mar 7, 2017

- Posts

- 39

- Reaction score

- 0

- Location

- Northwest Florida

- First Name

- Mike

- Truck Year

- 1985

- Truck Model

- K10

- Engine Size

- 305

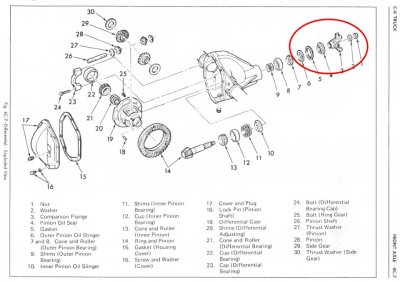

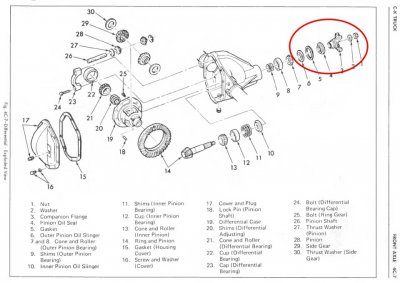

New owner here of a 1985 K10. I have a front differential leak near companion flange. It appears like I would basically remove the flange and replace the pinion oil seal. A few basic questions:

1) Can you get the seal? Wondered how to get part numbers.

2) Should I replace the gasket also?

3) Can this be done externally without rebuilding the differential? The front axle does not leak from anywhere else and runs exceptional well with little noise.

Thank you for any insight.

M

1) Can you get the seal? Wondered how to get part numbers.

2) Should I replace the gasket also?

3) Can this be done externally without rebuilding the differential? The front axle does not leak from anywhere else and runs exceptional well with little noise.

Thank you for any insight.

M

Attachments

Last edited: