R8rPhan

Full Access Member

- Joined

- Feb 5, 2017

- Posts

- 452

- Reaction score

- 42

- Location

- California

- First Name

- Mark

- Truck Year

- 1973 (1979?)

- Truck Model

- C10 long bed (Frankenstein truck)

- Engine Size

- 307

Put the enine at TDC compression stroke..

Pulled the wires and distributor cap..

Marked where everything is pointing...

Yanked the distributor...

Noted where rotor is pointing after the pull..

Pulled the coil and mount...

Excellent, ready to put new HEI in...

Went to change out oil pressure sender (new one comes with digital gauge kit) while everything is out of the way..

Put wrench on fitting under sensor....

Gave a little tug...

SNAP!!!

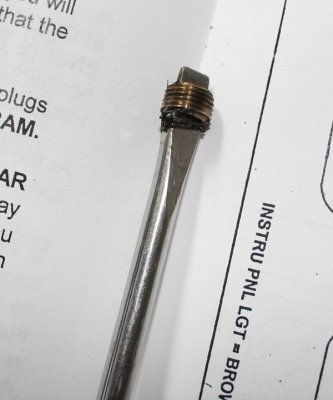

little brass nipple screwed into block snapped off, and threads are still in block!!!

(Insert all kinds of bad words here!)

(insert acceptance, then crying here)

Looking for easy outs...

Can't find (probably don't have anything that small anyways)

Miles from anywhere...

Thinking I'll have to drill it out and run tap in there....

No idea what size it is...

HELP!!!

Anyone know what size tap and drill I need?

Any other ideas????

Why the hell is the wall on this brass nipple so freaking thin????

Pulled the wires and distributor cap..

Marked where everything is pointing...

Yanked the distributor...

Noted where rotor is pointing after the pull..

Pulled the coil and mount...

Excellent, ready to put new HEI in...

Went to change out oil pressure sender (new one comes with digital gauge kit) while everything is out of the way..

Put wrench on fitting under sensor....

Gave a little tug...

SNAP!!!

little brass nipple screwed into block snapped off, and threads are still in block!!!

(Insert all kinds of bad words here!)

(insert acceptance, then crying here)

Looking for easy outs...

Can't find (probably don't have anything that small anyways)

Miles from anywhere...

Thinking I'll have to drill it out and run tap in there....

No idea what size it is...

HELP!!!

Anyone know what size tap and drill I need?

Any other ideas????

Why the hell is the wall on this brass nipple so freaking thin????

Last edited: