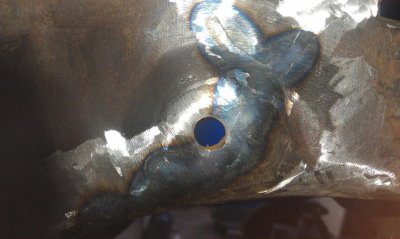

I would grind the booger welds down and clean it up, wire wheel the whole section and give it a good looking over, hammer that lower right hole, the metal around it, back into shape. Then MIG it all back together inside and out. The left top one may be hard to get to from the inside but that's where a MIG is a little easier to work with. Grind your work again (but not all the way out) and then weld on one of these patch kits...

http://autoplicity.com/products/392...o4&network=g&gclid=COvKorXz4rICFcKPPAodRHkA_A

You'll have to have some propane or mapp gas to heat it/shape it as you go, to get all the contact points close enough to the frame for welding.

As for the broken bolt, that's a tough one. It'll definitely need to come out since there's only 4 bolts it really needs all of em. You could try to drill it out and try using the stub sticking out the other end to get it out, using vice grips. You'll probably have to cut some off so it can screw out but leave enough to get vice grips on. And definitely drill it as much as you can without going too big and getting into the threads. Soak it good with penetrating oil, and you may want to try using a little heat on the steering box around the bolt but not on the bolt itself. Just don't use too much heat since it could hurt the seal at the pitman arm or in the end cap.

Yeah man, looks much better, and I'm certain that piece was off some other brand truck. You gonna get a patch to put on there too? I would at least make a plan to do the brace kit if not doing the patch.

Yeah man, looks much better, and I'm certain that piece was off some other brand truck. You gonna get a patch to put on there too? I would at least make a plan to do the brace kit if not doing the patch.