Ricko1966

Full Access Member

- Joined

- Apr 11, 2017

- Posts

- 4,054

- Reaction score

- 5,890

- Location

- kansas

- First Name

- Rick

- Truck Year

- 1975

- Truck Model

- c20

- Engine Size

- 350

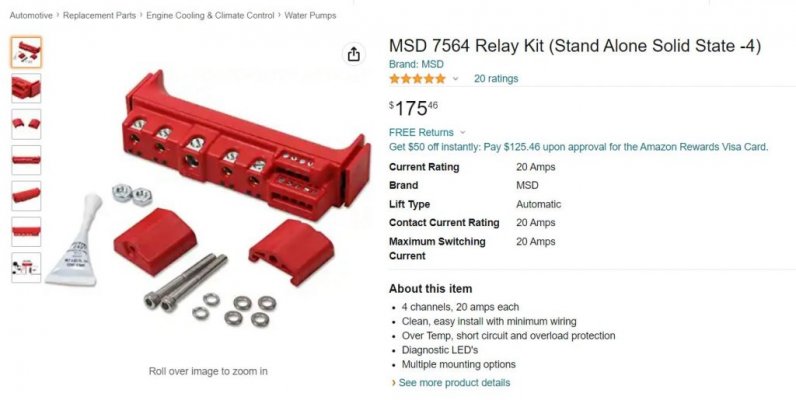

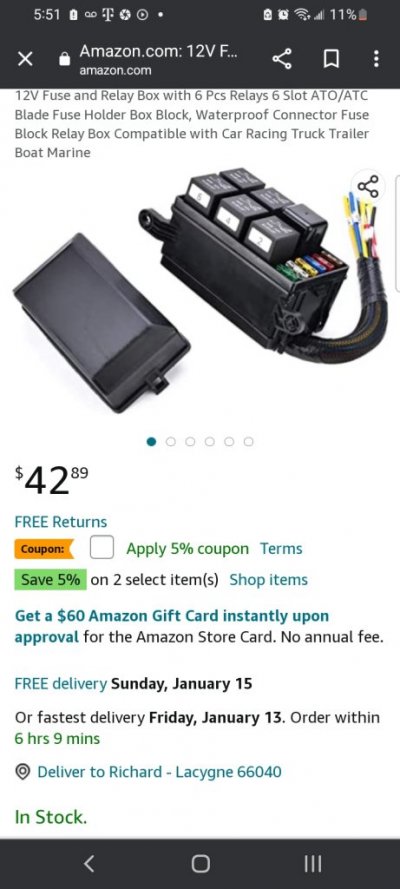

I've been on several posts where people have been trouble shooting this or that,but it's clear they have no idea what a relay is,how a relay works,or why they need a relay. I am not teacher or an engineer just a dumb old mechanic trying to give you guys the benefits of what I've learned. There's a pic you can blow up to understand this. A relay is just a switch controlled by an electro magnet when the magnet is powered up,it opens or closes a switch to turn something on or off.Why would you use a relay?,to turn things on and off at a certain time with 1 switch powering multiple relays. Another one would be the electromagnet uses very little current but the switch in the relay can handle lots of current. Your starter solenoid is a good example,your ign switch in the crank posution powers the electromagnet which closes the contacts and the starter cranks. The ignition switch would burn up trying to pass starter current. The relay pictured is a super common relay. 85 and 86 are the electro magnet. 30 is power in 87 and 87a are power out. If you look at that relay you can see power goes from 30 to 87a when the relay is off, it goes from 30 to 87 when the relay is on. Let's say I thought that relay wasn't working and I know it controls the fuel pump when the keys on. I can put a piece of wire in place of that relay, jump 30 to 87 my fuel pump should run. If it doesn't the relay isn't the problem. To test that relay if I want to I can check continuity from 30 to 87a without the electro magnet,it should have continuity, now power and ground 85 and 86 your continuity should change to 30 and 87.

When you jumper a relay, really your jumper should have a fuse on it,in case there's a short on the output wire. I rarely do it that way it's a paper clip or whatever is closest to me. Ymmv

When you jumper a relay, really your jumper should have a fuse on it,in case there's a short on the output wire. I rarely do it that way it's a paper clip or whatever is closest to me. Ymmv

Attachments

Last edited: