TheC5Surgeon

Member

- Joined

- Aug 2, 2021

- Posts

- 31

- Reaction score

- 14

- Location

- Panhandle of FL

- First Name

- Matthew

- Truck Year

- 1976

- Truck Model

- C20

- Engine Size

- 454

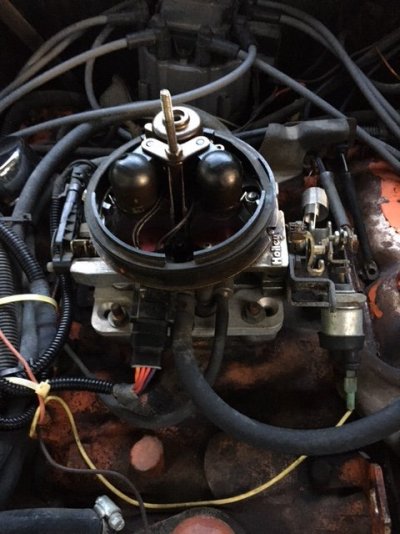

Just bought my first square body. Its a 1976 C20 burb 454. Its a beautiful truck with extremely little body and frame rust. The previous owner did a tbi conversion. Long story short the truck does not like to idle, wants to bog down when given above 50% throttle, and seems to be running extremely rich. I would like to convert it back to a carbureted setup but am completely new to carbureted world. I have done some searches but most of the resources seem to be for conversion from carb to tbi. My questions to start would be: what parts needed to convert to carb system and what resources would be best to have a little guidance through the build? I attached some pics of the truck and fuel system.