fuel starvation

In my case i was having a fuel starvation problem,, sometime it would go,, sometimes it would stumble..

going down the road and stand on it and it would fall flat on its face...

so here are the things i went through to solve the problem..

i tryed a new edelbrock/carter mechanical fuel pump,, it helped but didnt fix it.

i hooked up a fuel recirculation system as to where the fuel coming from the pump to the carb had a filter with an extra connection to it and routed it back to the tank so fresh cool fuel was always getting to the carb,, it helped alot,, but my tanks only have 2 lines and the smaller one is a vent only to the vapor canister and fuel wouldnt go back into the tanks..

so i pulled the tanks and the senders and removed the stopper from the vent line so fuel would pass through,, also while i was at it,, i put the left sending unit in the right tank and the right in the left tank,, so the pick up tube was pointing to the rear of the tank and tore off the sock and extended the puckup tube with some REAL good fuel line that wont go to **** by the gas eating it...

reason being? when i would stand on it all the gas would go to the back of the tank and the pickup tube was pointing forward and would starve for fuel,, there wasnt any there to pickup,, and "old race/bracket car trick"..

it also helped when climbing up long up hill runs..

put it back together and that solved most of the problem i was having,, even the hot starts when the pressure was still in the fuel lines when shut off and would flood the carb and drip down past the venturies/ fuel dripping....

still didnt completely fix the problem of surging and bog..... so? loosing more gray hair and im already bald,, lol,, i got a carter self regulating electric fuel pump consistent 6# of pressure and put it next to the tank switch,, that helped some..

so tore the carb apart and i had them spring loaded needle and seats in it for off road? they dont work,, i tryed every damn float settings and nothing would help,, so tore the carb apart again and put in the pink tipped needles and made sure the floats were LEVEL with the top of the carb top plate when upside down,, and let the float drop go all the way down to the bottom of the carb,, so when i shook the carb after the top was back on ya could hear the floats hit the bottom of the carb..

i also drilled tiny lil holes in the gas cap center on the inside so pressure wouldnt build up in the tanks? and also so the tanks wouldnt create a vacuum in them from fuel being removed from them going down the road..

put it all back on/together,, God damn it was fixed,, no fuel starvation,, no bog,, no top end hunting for fuel......

.

every lil bit helps

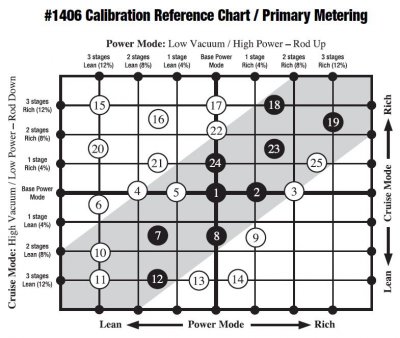

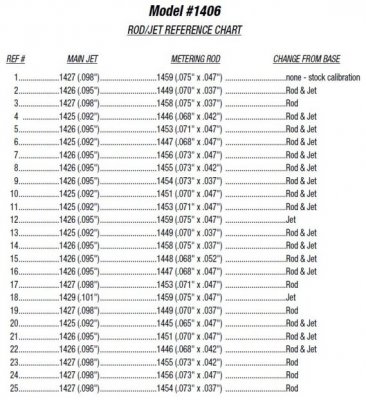

then i got the air fuel meter and finished dialing in the carb.....

.

.