MtBraun

Full Access Member

- Joined

- Sep 27, 2017

- Posts

- 455

- Reaction score

- 306

- Location

- South Dakota

- First Name

- Matt

- Truck Year

- 1984

- Truck Model

- K10

- Engine Size

- 632

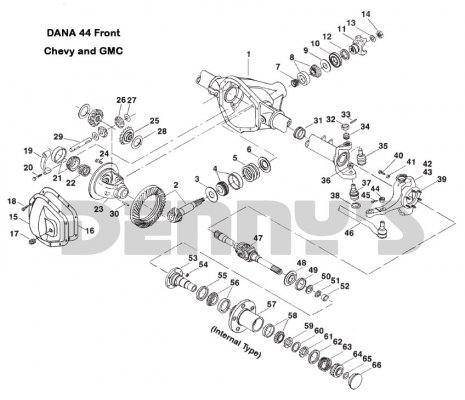

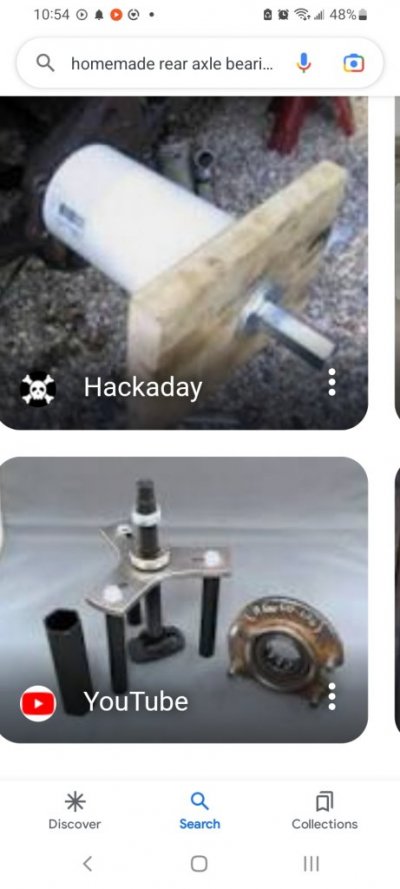

Rebuilding a D44 front. Upon disassembly there was no shim stack behind the inner pinion bearing race. Other anomalies suggest to me it wasn't assembled correctly anyway. I did not run a pattern (probably should have) prior to disassembly. I'd like to measure pinion depth, but don't want to buy the $600 tool for one setup. None of my local shops have the tool either. I'm hesitant to buy the cheap $30 tool but perhaps someone here can speak to its effectiveness. Or are there other tricks for measuring this without the expensive tool? Thanks!