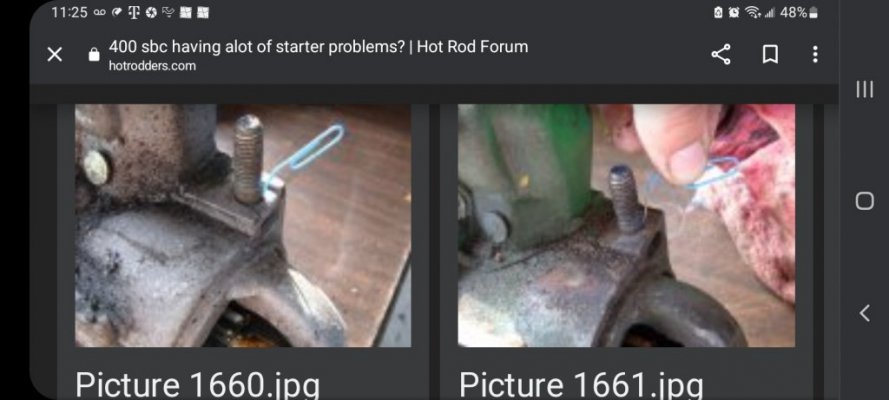

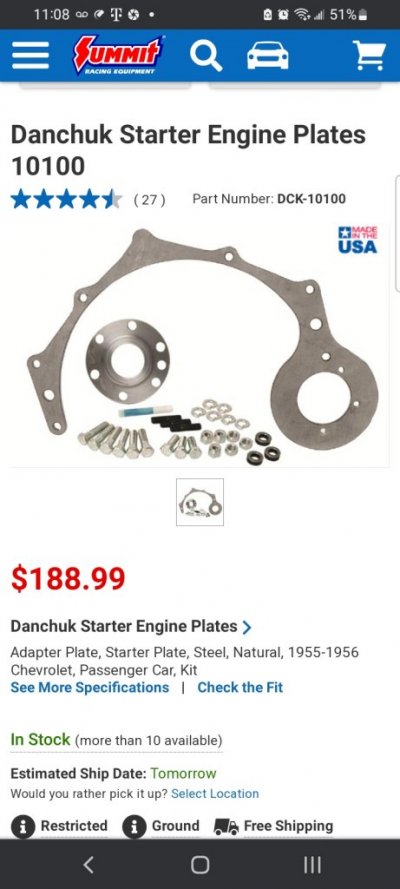

Okay I'm home now,more time to write,not the first time I've seen this and fixed it more than once. Most everyone knows a triangle is a very strong structural shape. Your starter mounting was a triangle when new, 2 bolts at the nose and a third at the tail. With a missing bracket now your starter mount is 2 bolts in a flat plan and if the engine kicks back while the starters cranking it pushes back on the starter twisting it and breaks the outer bolt hole. I would bet you money, if I was there to look at it with you that the rear bracket is missing. Everything I said in my first post I have done and it worked. Since you have a k you actually are at an advantage. You are going to have to change the flex plate,imho it's just as easy to pull the engine as it is to pull the transfer case and transmission. Since I have not done this before because I never pulled the engine to change the flex plate. I'd make sure that if I made a stud for that outter hole that I would still be able to r+r the starter if so I'd make a stud,sink it as deep as I could in the block,then braze the broken outer bolt hole getting as much brass into the Crack and into the stud threads as possible. Put it back together with a nose cone like I said and the rear bracket, good as new. You could preheat the area with oxy,acetylene and weld it with high nickel rod but I think you'd have just as good of luck with brass.