- Joined

- Aug 29, 2010

- Posts

- 47,014

- Reaction score

- 9,009

- Location

- OKC, OK

- First Name

- HotRod

- Truck Year

- 85 K20 LWB

- Truck Model

- Silverado

- Engine Size

- 454 - Turbo 400 - 3.73

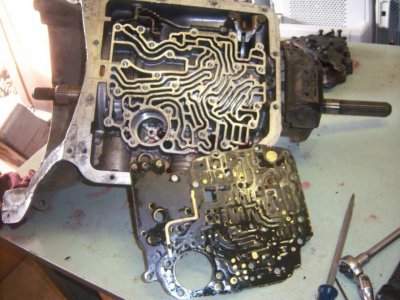

As many of you were aware. I am building a TH350 for my brothers El Camino. I tore his core apart and didn't like a few things about his case, where it has been previously cut and shaved and weakening the bell housing area. So, I have to donate him one of my Th350 cores and this time, no longer in any kind of hurry, decided to take some pics and post up a thread that might be helpful to some of you.

This paticular core I bought for $20. You'll see later why I decided to buy it. It is a short tail shaft of 6in and appears to be a passenger car transmission but was taken out of a 70 Chevy Pickup.

This paticular core I bought for $20. You'll see later why I decided to buy it. It is a short tail shaft of 6in and appears to be a passenger car transmission but was taken out of a 70 Chevy Pickup.