- Joined

- Aug 29, 2010

- Posts

- 47,014

- Reaction score

- 9,013

- Location

- OKC, OK

- First Name

- HotRod

- Truck Year

- 85 K20 LWB

- Truck Model

- Silverado

- Engine Size

- 454 - Turbo 400 - 3.73

For those whose tailgate latches and mechanisms that aren't working right or at all.

First big tip is to bring your patience. Manipulating the main mechanism in and out of the tailgate will require you to hold your mouth just right and all that good stuff, as well as getting the rods connected. So muster up all the patience you can.

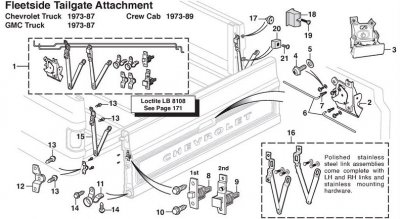

This diagram from the LMC Truck part catalog is a great reference of what your dealing with.

Just to note, If you're tailgate has a band, You DO NOT have to remove it to make these repairs.

First big tip is to bring your patience. Manipulating the main mechanism in and out of the tailgate will require you to hold your mouth just right and all that good stuff, as well as getting the rods connected. So muster up all the patience you can.

This diagram from the LMC Truck part catalog is a great reference of what your dealing with.

Just to note, If you're tailgate has a band, You DO NOT have to remove it to make these repairs.