- Joined

- Aug 29, 2010

- Posts

- 47,014

- Reaction score

- 9,013

- Location

- OKC, OK

- First Name

- HotRod

- Truck Year

- 85 K20 LWB

- Truck Model

- Silverado

- Engine Size

- 454 - Turbo 400 - 3.73

Whoever rebuilt this transmision previously was an idiot. This makes about the 5th problem I have found in this transmission. None of the problems with this transmission were due to wear or high performance. All have been faulty builder. Someone who should probably be flipping burgers or shoveling **** for a living.

So, onto another direct drum, Lets start over. Now you get to see a newer or later style direct drum assembly.

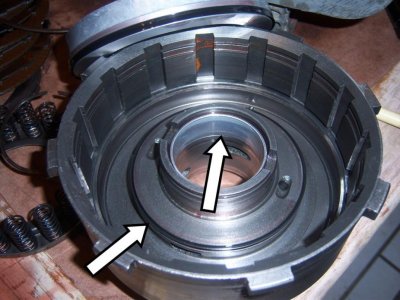

Here is what the top side of the Direct Drum and Overrun Clutch looks like assembled. Simply pull the snap ring off, then remove the retainer ring.

I have already felt the roller clutch and it feel just great. Overruns in one direction, and grabs hold in the other, so I don't see the need to remove the outer race gear, and clearly the roller clutch assembly does not appear to be damaged in anyway. So I will put the retainer and snap ring back on and call it good and inspected.

Now I flip the drum over, and remove the snap ring and pressure plate. Notice the return spring retainer looks a bit differant than the last one??? This is the newer or later style.

Remember this is donor drum from a core transmission I had from a guy who broke the input shaft on a low mileage rebuild transmisison. These clutches look to be in like new condition. I will save these clutches for later use. I will not use used clutches to rebuild a customers transmission, but I would not hesitate a bit to use these clutches in one of my own vehicles, or buddy who needs a good deal on a trans rebuild. You can get a complete seal kit for a Th350 for less than $20. With that seal kit, you can go thur the whole transmission, reuse your steels if not badly damamged, and if so, I have plenty of good used steels, and use clutches like these and rebuild a transmission and I'd consider it as good as a new rebuild and expect a long full life out of it. The Th400 transmission in my DD is a completly rebuilt transmission, good as new, and it cost me $0. I did buy the kit, but I had sold the donor case for the amount to cover all my parts and 3 gallons of trans fluid. I like FREE recycled parts !!!

Its nice how the later style return springs and retainer are all one piece. Makes for a bit of time savings, and more importantly, your springs don't run off and then you have to short the springs like the last idiot did. I have to wonder WTH he was thinking !!!

So, onto another direct drum, Lets start over. Now you get to see a newer or later style direct drum assembly.

Here is what the top side of the Direct Drum and Overrun Clutch looks like assembled. Simply pull the snap ring off, then remove the retainer ring.

I have already felt the roller clutch and it feel just great. Overruns in one direction, and grabs hold in the other, so I don't see the need to remove the outer race gear, and clearly the roller clutch assembly does not appear to be damaged in anyway. So I will put the retainer and snap ring back on and call it good and inspected.

Now I flip the drum over, and remove the snap ring and pressure plate. Notice the return spring retainer looks a bit differant than the last one??? This is the newer or later style.

Remember this is donor drum from a core transmission I had from a guy who broke the input shaft on a low mileage rebuild transmisison. These clutches look to be in like new condition. I will save these clutches for later use. I will not use used clutches to rebuild a customers transmission, but I would not hesitate a bit to use these clutches in one of my own vehicles, or buddy who needs a good deal on a trans rebuild. You can get a complete seal kit for a Th350 for less than $20. With that seal kit, you can go thur the whole transmission, reuse your steels if not badly damamged, and if so, I have plenty of good used steels, and use clutches like these and rebuild a transmission and I'd consider it as good as a new rebuild and expect a long full life out of it. The Th400 transmission in my DD is a completly rebuilt transmission, good as new, and it cost me $0. I did buy the kit, but I had sold the donor case for the amount to cover all my parts and 3 gallons of trans fluid. I like FREE recycled parts !!!

Its nice how the later style return springs and retainer are all one piece. Makes for a bit of time savings, and more importantly, your springs don't run off and then you have to short the springs like the last idiot did. I have to wonder WTH he was thinking !!!

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

Last edited:

Back in those days, we didn't drink at the races. No place for that in that environemnt. That's how people get killed. So I was sober on the weekend going to the drags, but during the week I did my partying while building transmissions. So many of the transmissions I built out in the garage... lets put is this way, the fridge was right next to my roll a way and my 60gal air compressor.

Back in those days, we didn't drink at the races. No place for that in that environemnt. That's how people get killed. So I was sober on the weekend going to the drags, but during the week I did my partying while building transmissions. So many of the transmissions I built out in the garage... lets put is this way, the fridge was right next to my roll a way and my 60gal air compressor.